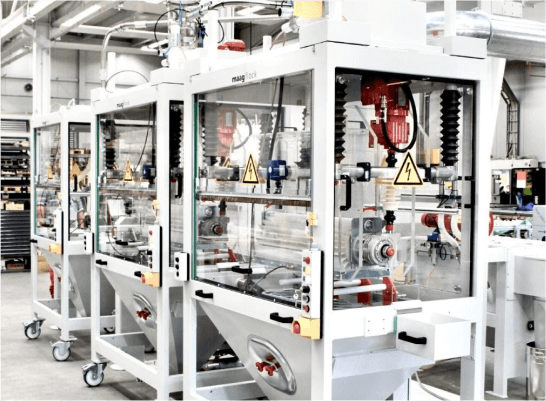

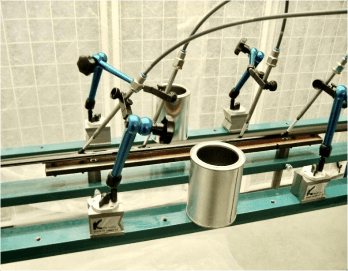

For electrostatically shielded areas, electro-pneumatic flocking is used so that recesses and undercuts can also be ideally flocked, depending on the product geometry.

The spectrum of possible applications of profile flocking is very large, whether building materials, rubber profiles, aluminium profiles or profiles for the automotive industry, the flocking of profiles can be used in many different ways in other specified areas.

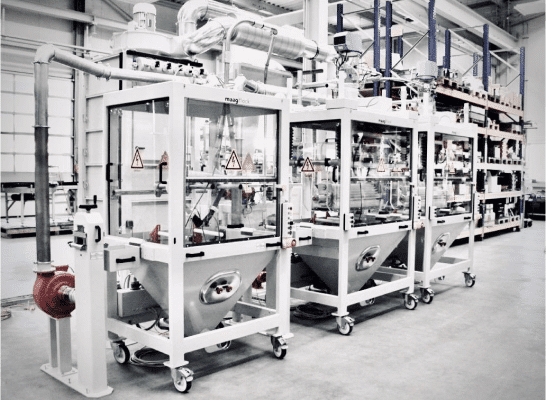

The system offers you an all-round concept for targeted profile flocking and quality assurance, produced for you in Germany.

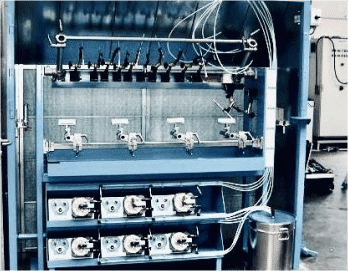

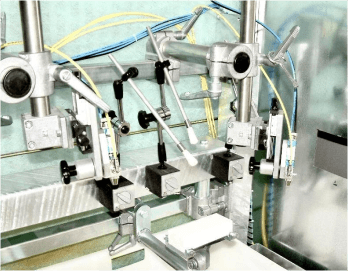

Depending on the profile geometry, several adhesive application modules are used, which are set up according to the profile geometry. Adhesive application is carried out with the aid of automatic micro-spraying machines or with brushes that are supplied with adhesive by pressure vessels or hose pumps. Furthermore, methods such as sliding blocks are used and individual customer requirements are constructed.

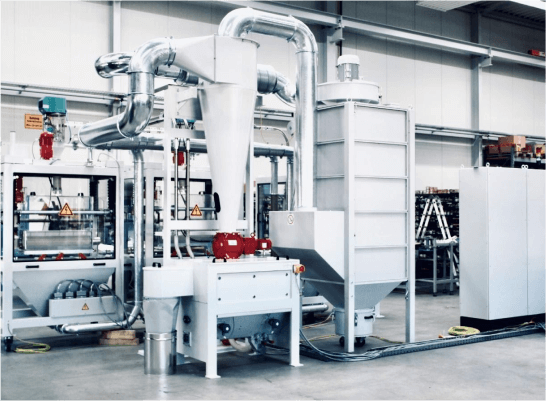

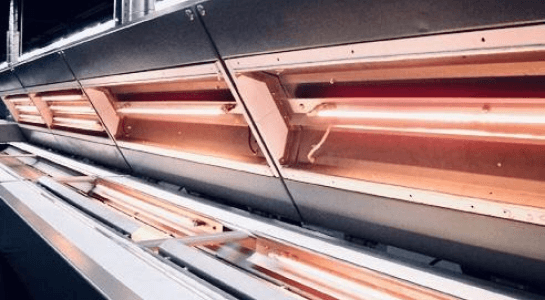

In this system, drying takes place via hot air in combination with an infrared heating section at the dryer inlet, whereby rapid heating of the profile surface and subsequent adhesive drying take place evenly. In addition, the drying can be adapted to the customer's specific requirements, e.g. via water drying or vacuum drying.

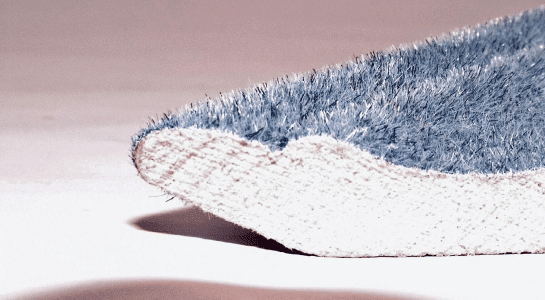

Building materials such as polystyrene develop a better technical quality as well as an optical upgrading of the raw material through flocking.

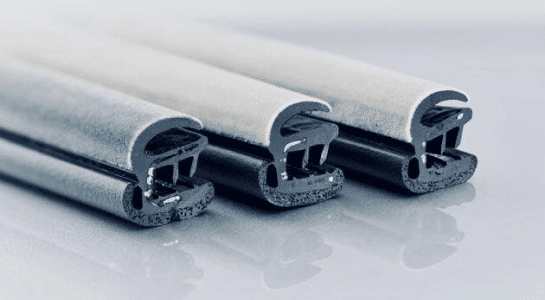

Profile flocking of rubber in the automotive industry, for optimum sliding properties without friction noise and to achieve an optimum seal. Rubber profiles can be flocked at up to 30 m/min, whereby undercuts are flocked electrostatically-pneumatically with the Pf-PL.

The flocking of building materials such as wood can be ideally realized with the profile flocking machine. During flocking, properties such as sliding properties, noise protection or thermal insulation are promoted.

Contact us and discuss your project today!