Pre-treatment

The object to be flocked, regardless of whether it is a straight surface, rotationally symmetrical parts, hollow bodies or other shapes, should be cleaned or pre-treated in the first step, depending on the existing surface condition. This serves to prevent possible adhesion problems between the substrate and the adhesive. The causes of adhesion problems are usually dirt, aging, the material condition or the too low surface tension of the substrate.

Common methods are treatment with solvents, mechanical roughening, the application of primers or undercoats and plasma coating.

Flock Adhesive application

After the substrate has been pretreated, the flock adhesive is applied. Here it is important to select the adhesive based on the subsequent use, so that it is suitable for the respective application. Information and advice on the selection of the right adhesive can be requested from various manufacturers. Before the adhesive is actually applied, the surface tension and condition of the substrate should be checked. In the best case, the adhesive is tested in advance in conjunction with the substrate surface.

The adhesive can be applied by brushing, rolling, printing, spraying or squeegeeing. Only the areas to be flocked are coated with adhesive. To protect areas that are not to be flocked, stencils or adhesive tape can be used. In the case of squeegeeing or printing, the adhesive surface is already defined.

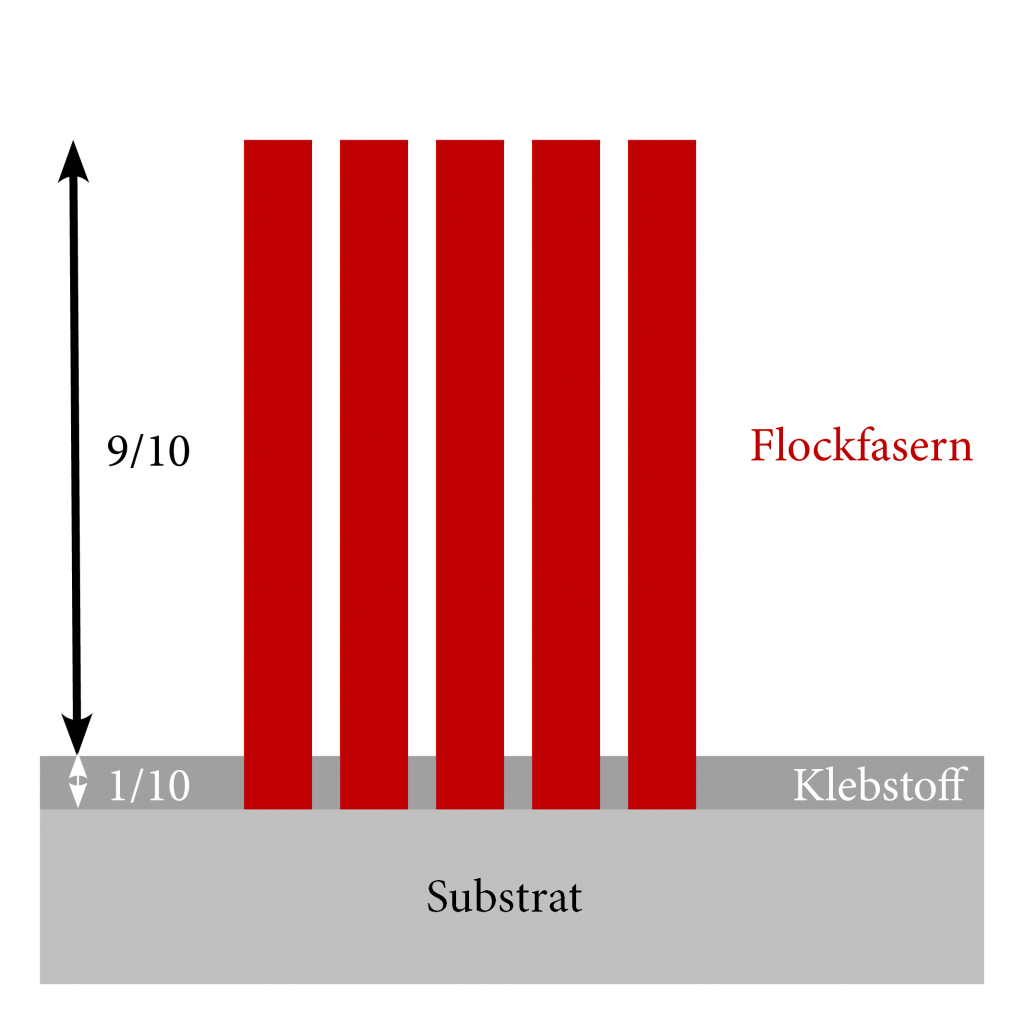

When applying the adhesive, make sure to achieve an even layer thickness. The following rule of thumb applies: the layer thickness of the dry adhesive should correspond to 10 % of the flock fibre cut length. This ensures optimum anchoring of the fibres in the adhesive.

After application of the adhesive, the substrate must be flocked promptly, because as soon as the adhesive has dried slightly, the flock fibres can only be anchored with difficulty. Therefore, when selecting the adhesive, it is important to consider how much time remains between the application of the adhesive and the flocking. This is called the open time.

Flocking

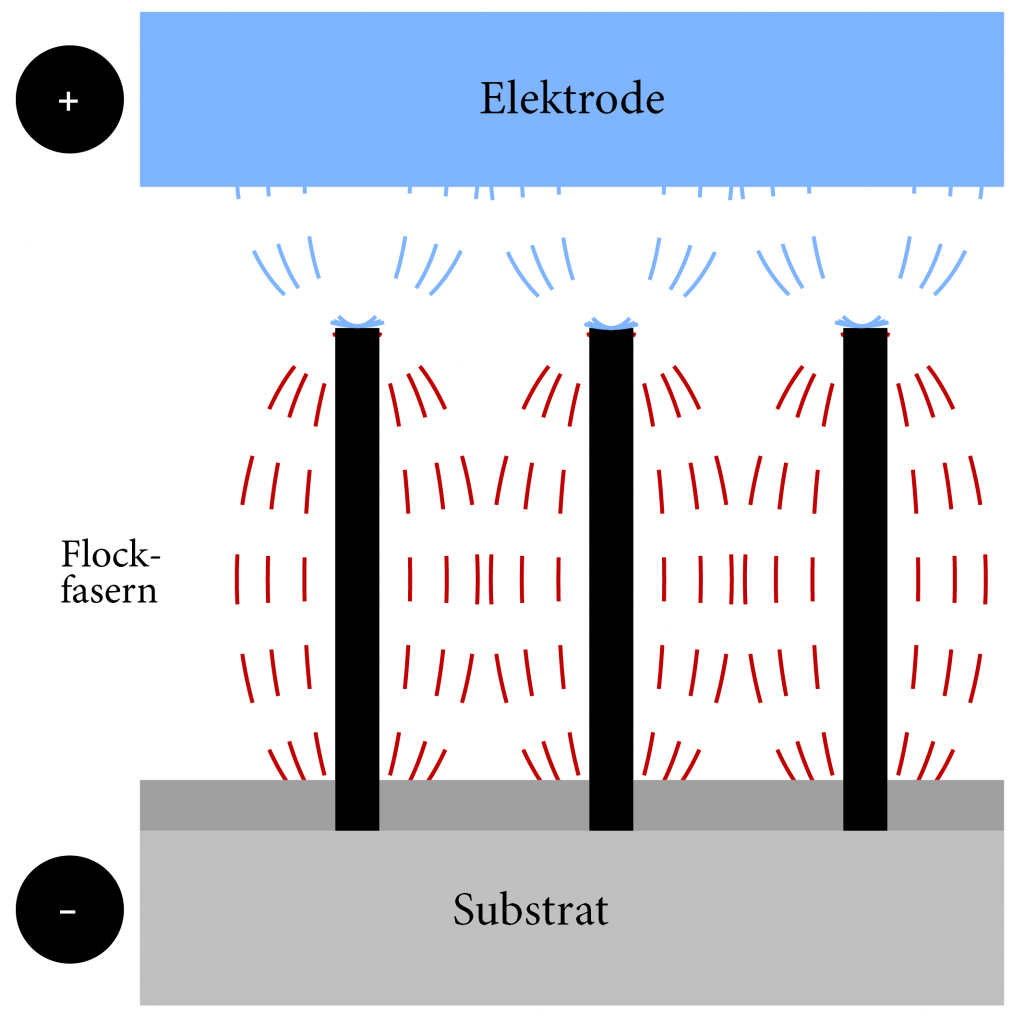

After pre-treatment and adhesive application, the actual flocking can take place with the help of an electrostatic field. This is done manually, semi-automatically or fully automatically, electrostatically or electrostatically-pneumatically, depending on the shape of the object to be flocked. The electrostatic charge is used to bridge resistance in the form of the interaction of the air conditions, the distance of the electrode to the substrate, the conductivity and the voltage. The flock fibers are charged to a voltage of 5-70 kV. The field lines of the electrostatic charge cause the flock fibers to repel each other and align along the field lines. This results in the flock fibres anchoring themselves vertically in the adhesive, as the field lines always strike the surface to be flocked perpendicularly. In the case of an electric field, a distinction can be made between three different types:

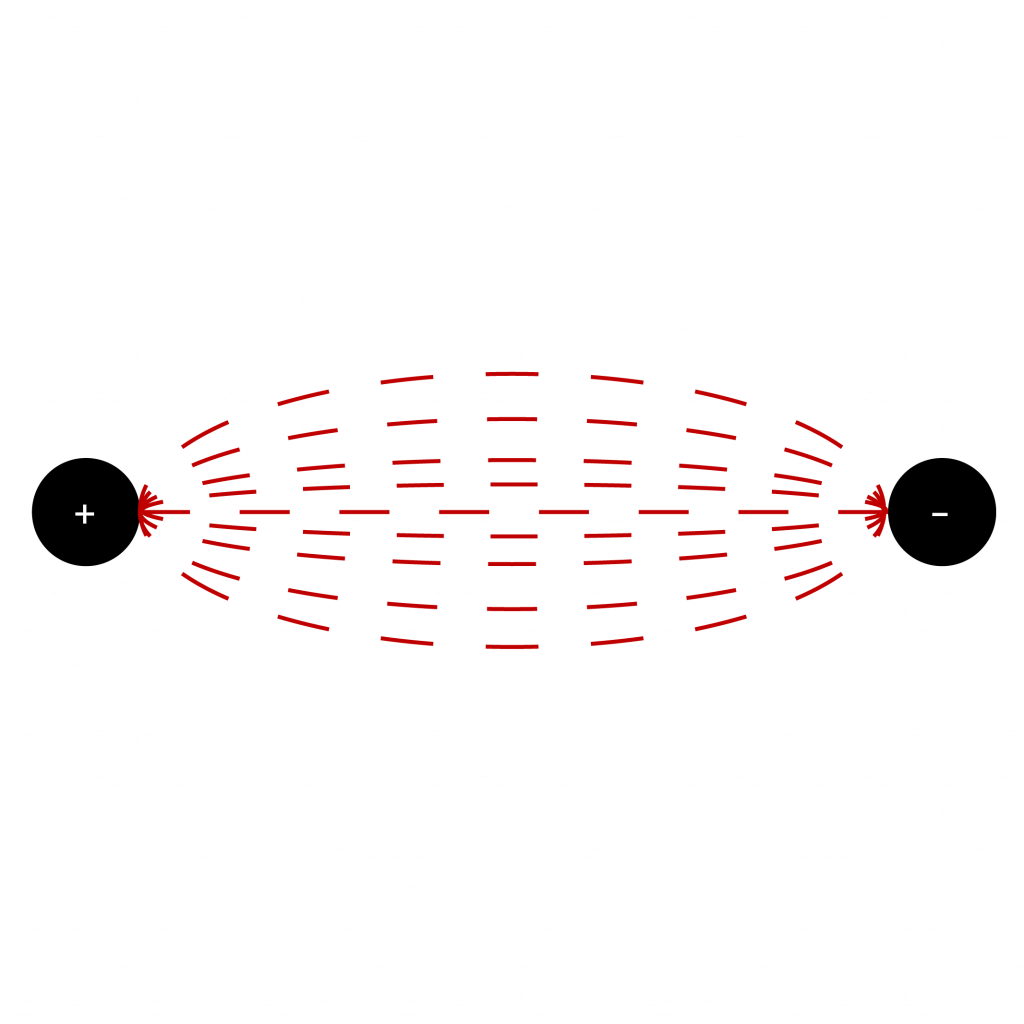

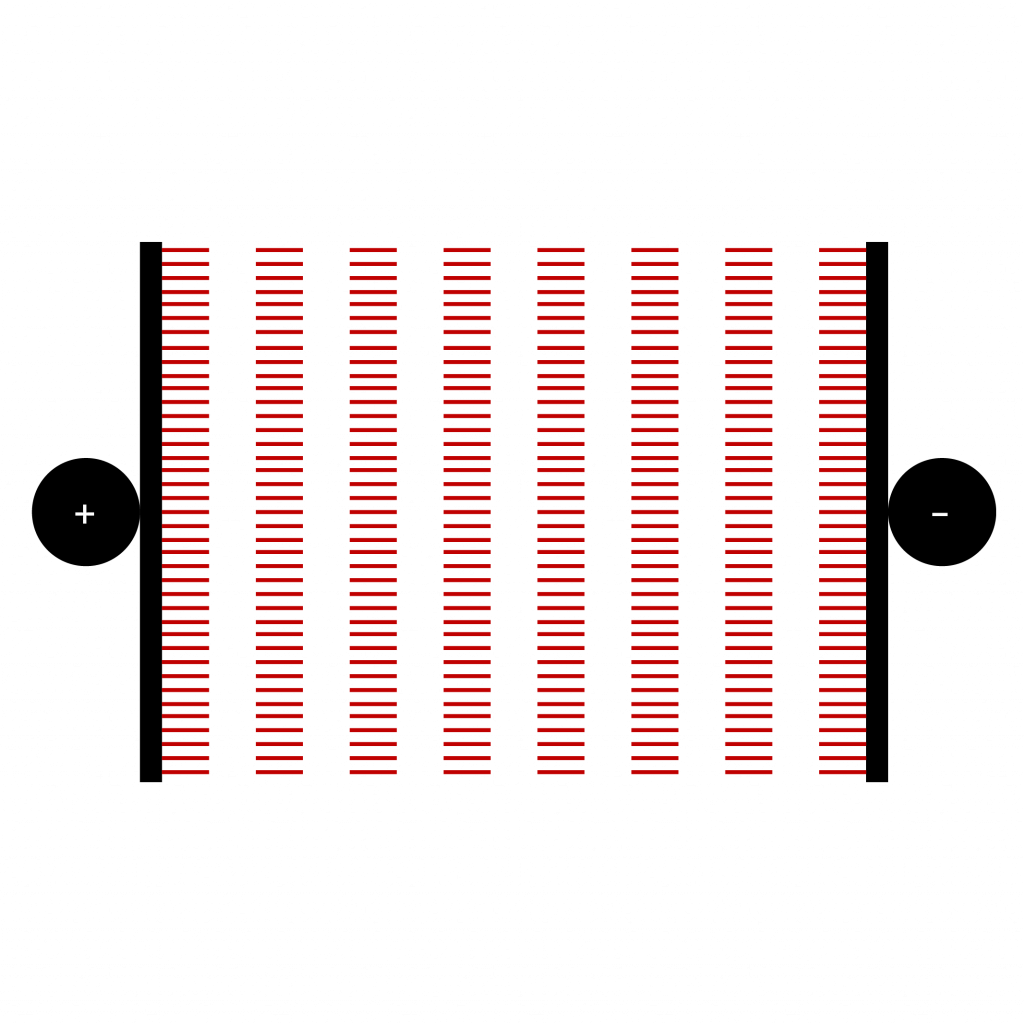

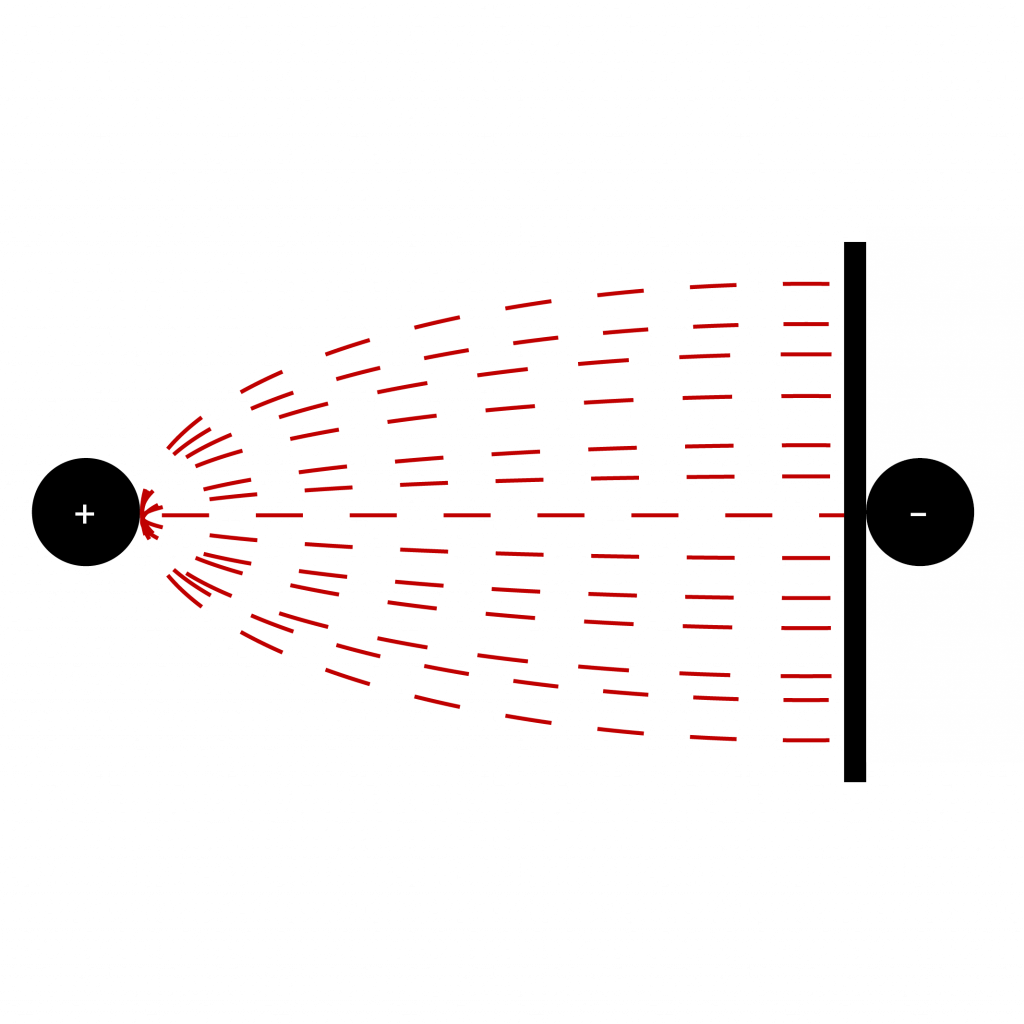

An electric field between two point charges, an electric field between two plate electrodes and an electric field between a point charge and a plate electrode.

The electrode in the flocking device forms the positive pole. It is crucial that the object to be flocked is connected to an earth cable and thus forms the negative pole.

Electrostatic field between two point charges

Electrostatic field between two plate electrodes

Electrostatic field between a point charge and a plate electrode

Influencing parameters for an optimal flocking result are the preparation of the flock fiber, the air conditions and the distance between the electrode and the substrate. It is important to consider the parameters not separately from each other, but in an interplay. Each of the individual parameters influences the others. For optimal flocking, the flock fibers must have sufficient electrical conductivity. This is possible due to the preparation of the fibres with coding products, metal salts, tannic acids or other substances that support the conductivity.

In addition, the flock fibres must have an ideal residual moisture in order to optimally develop their electrical conductivity. Therefore, the recommended temperature and humidity of the manufacturer must be maintained during the flocking process. The relative humidity during flock processing is between 55 % and 65 %. In addition to the humidity of the flock fibre, this also determines the optimum conductivity.

Furthermore, the flock must be conditioned. If it is in a storage container for several hours, the conditioning can deteriorate so that optimum flocking is no longer possible due to changed process parameters.

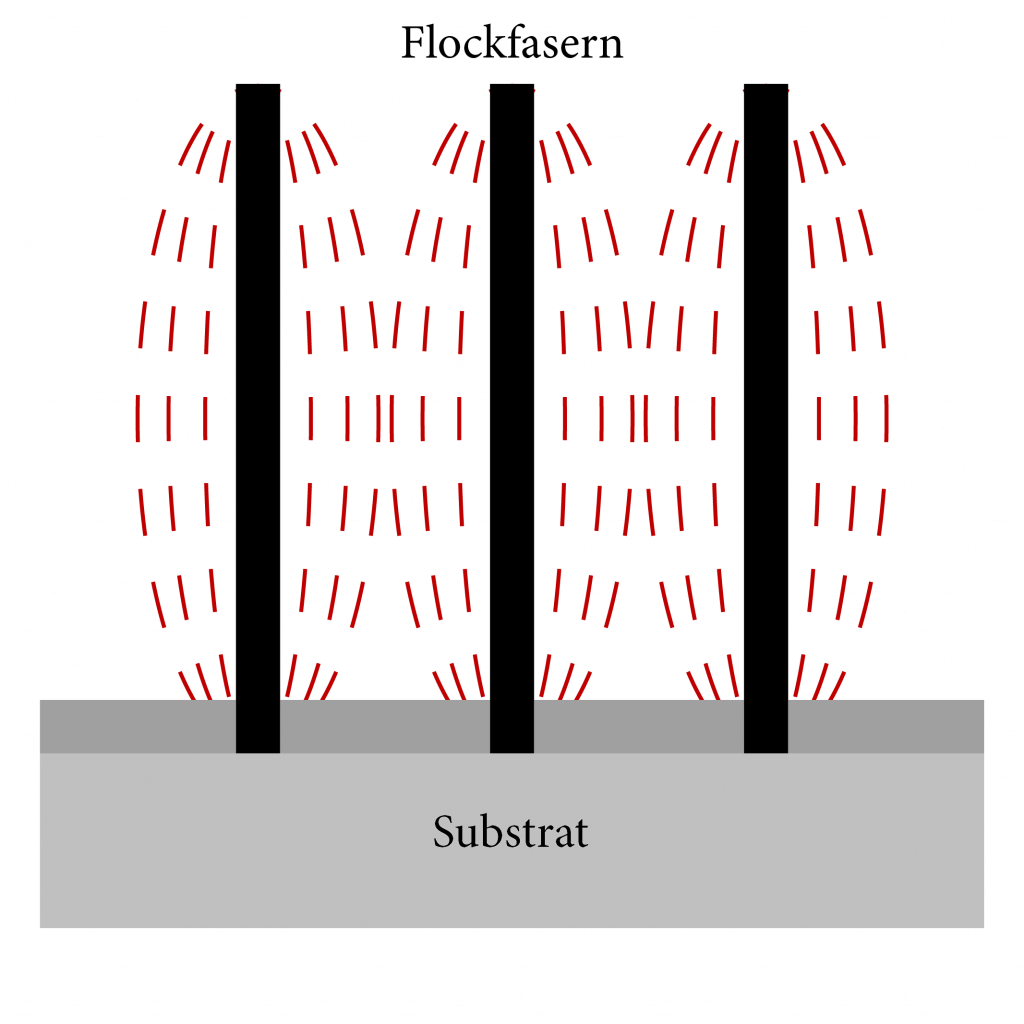

After flocking a substrate, only about 10 % of the surface is actually covered with flock fibers. This is due to the electrostatic charge that the individual flock fibers have. Due to the voltage, each individual fiber creates an electrostatic field around itself. This means that the next fibre can only be anchored again at a certain distance. The size of the field depends on the length of the flock fibre, whereby the longer the fibre, the larger the electrostatic field. The resulting air or hollow spaces serve and influence the most diverse functions of flock:

As soon as the first fibers are anchored in the adhesive or on the substrate, they form further field lines upwards in addition to the field lines around them, which also determine the distance between the fibers like the other field lines.

In addition to the electrostatic fields that form around the individual fibers, the distance between the electrode and the substrate is important for flocking. The greater the distance between the positive and negative pole, the more difficult the flocking and the worse the result.

However, this can be prevented by increasing the kilovolts. That is, the greater the distance between the electrode and the substrate, the more voltage is needed.

With flocking, there is a choice between two different types or devices: purely electrostatic flocking or electrostatic-pneumatic flocking.

Electrostatic devices are especially suitable for flat and straight surfaces. This type of flocking can be carried out both in large industrial companies with large plants, as well as at home with small hand flocking devices for the private user.

The purely electrostatic flocking can also take place in the opposite direction to gravity, i.e. from bottom to top. During the process, the flock jumps back and forth between the two poles until it is anchored in the adhesive or has fallen out of the field.

Electrostatic-pneumatic flocking is used for objects that are concave or recessed. This is due to the so-called Faraday cage, which ensures that the charge is shielded and cannot penetrate into depressions or cavities. In electrostatic-pneumatic flocking, in contrast to purely electrostatic flocking, air is supplied to the electrode. This allows the flock fibers to break through the resistance in recesses and cavities. Because they follow the least resistance along the air flow.

In addition, whether purely electrostatic or electrostatic-pneumatic flocking is used, an auxiliary electrode can be used, which has a supporting effect at larger distances between substrate and electrode and maintains the electrostatic charge.

Drying

After flocking, the flocked objects are dried in the air or in an oven. Drying can be done by hot air, infrared radiation or a vacuum. Various parameters have an influence on the drying process: On the one hand, the heat or temperature, the humidity in the dryer and the air exchange or circulation.

Explicit information on drying can be obtained from the adhesive manufacturer.

Cleaning

After drying, the object is cleaned to remove the excess flock fibres. This can be done by blowing, vacuuming, brushing or washing.

So-called ionized air can also be used as part of the cleaning process. This is created with the help of ionizers, which generate oxygen ions by electrically ionizing molecules. As soon as this is blown onto a surface, the material on the surface, i.e. excess flock fibres, is charged or discharged. Due to this, loose flock fibers lose their adhesion to others and can thus be removed.