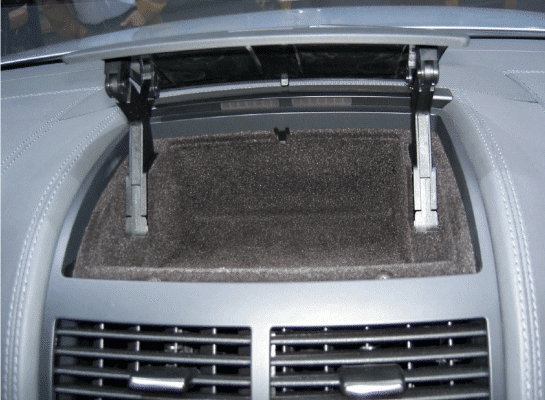

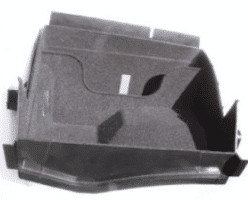

The glove box flocking system offers the ideal conditions for the large-scale production of intricately designed three-dimensional objects using automated and innovative flocking technology. The flocking system has already proven itself over decades in the automotive industry, from glove boxes to center consoles.

In this case, the system design covers the large-scale production of several hundred thousand pieces, complicated three-dimensional objects, and requires a minimum of manpower.

The electrostatic and pneumatic flocking technique is used for the ideal flocking of concave as well as convex geometries.

The prevention of noise as well as the pleasant feel and the beautiful design, improve the high quality and functionality of each glove box. In addition, the flocked surface provides additional heat and cold insulation and protection against damage and scratches, ensuring safe storage in the glove box.

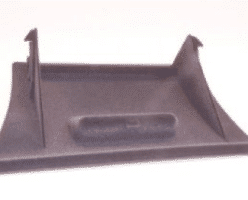

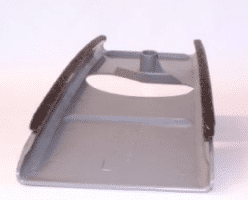

Three-dimensional moulded part flocking or glove box flocking is possible as an inline process, whereby the product is removed directly from the production machine with a handling device and then automatically runs through the flocking process.

Furthermore, there is the possibility of offline flocking, in which case the object is transported to the material storage and automatically or alternatively manually inserted from there into the flocking machine.

The adhesive coating is applied in an air-conditioned robot booth. A handling robot loads the conveyor belt of the automatic adhesive coating line and removes the coated objects. They are then transported onto the conveyor belt of the automatic flocking line.

Flocking takes place in several flocking zones by means of robots or linear systems. All individual process steps can be automated by robots or carried out by manual distraction.

After the three-dimensional objects have passed through the pre-cleaning unit, they are removed by robot or manually and, where necessary, cleaned manually by an operator, resulting in a final optical quality control.

The products are then palletised or conveyed onto a conveyor belt.

2. Pre-treatment

4. Flocking

5. Drying

6. Cleaning

7. Extraction

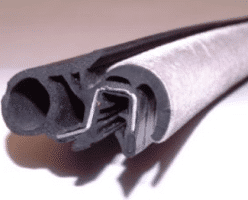

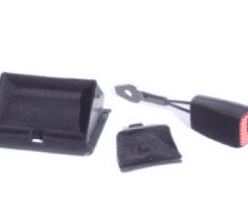

In addition, the flocking is used in the center console, the connector plugs and other storage compartments. In addition to the improvement of the surface quality and functionality, the user receives a high level of comfort in terms of noise reduction and aesthetics.

The colour can be selected individually according to the desired design, whereby there are no limits to the design. Even narrow spaces or complex geometries with undercuts can be flocked ideally using the innovative flocking technology and offer a uniform and qualitative surface of the product.

Contact us and discuss your project today!