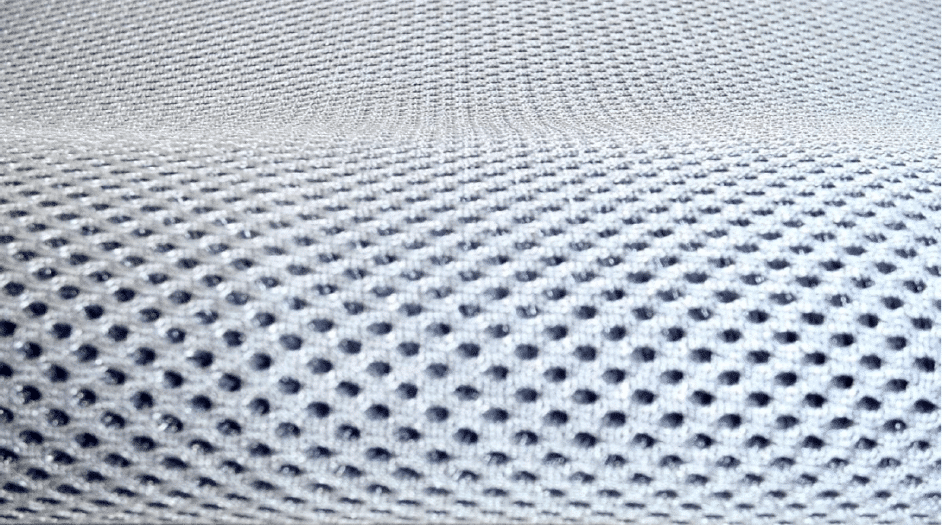

The roll-to-roll flocking can be used in many ways due to the wide range of carrier materials or substrates that can be flocked. It is already excellently used for flocking paper, cardboard, foil, rubber, felt or fabrics such as wallpaper, curtains and building materials such as corrugated sheeting and foil. There are no restrictions in the selection of the material and design to be flocked.

Elaborate patterns and colours can be individually designed and realised via the flocking process, whereby there are no limits to the creativity of the design.

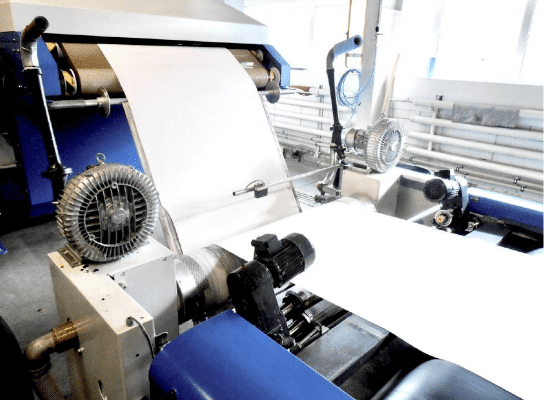

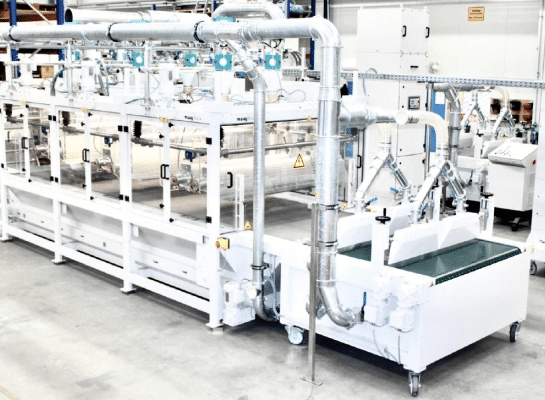

The flocking process is fully automated and is integrated, designed and delivered including the final trimming. Here, productions of three meters per minute belt speed up to 100 meters belt speed can be realized.

1. Withdrawal from material

2. Pre-treatment

4. Flocking

5. Drying

6. Cleaning

7. Extraction

By means of several single doses the belt speed can be increased and thus an increased production can take place.

The process of roll-to-roll flocking is based on a modular system, whereby individual customer requirements can be adapted and implemented.

In the flocking unit the products are transported in meter goods across to the metering box and flocked, whereby the flocking of very large surfaces is realizable.

The flocking process is fully automated from roll to roll, from the beginning with the pick-up and insertion of the roll until the final cleaning and rolling up of the finished product.

Contact us and discuss your project today!