Request form

Inquiry form for our online store With the help of this inquiry form you can send us a specific inquiry about our products. Please describe your request briefly and name the product in question. We will be happy to help you and send you further information and an offer if required. [form id="5172″ /]

MULF duct humidification

The MULF duct humidifier humidifies with the aid of ultrasonic technology. The various versions differ in humidification capacity from 400 m³/h to 1400 m³/h. During flocking, the air humidification serves the optimal room climate, to create the appropriate conditions during the flock application.

MULF direct humidification

The MULF direct humidification humidifies with the aid of ultrasonic technology. The various versions differ in humidification capacity from 2 l/h to 5 l/h. In the case of flocking, air humidification serves to create the optimum room climate, in order to create the appropriate conditions during the flock application.

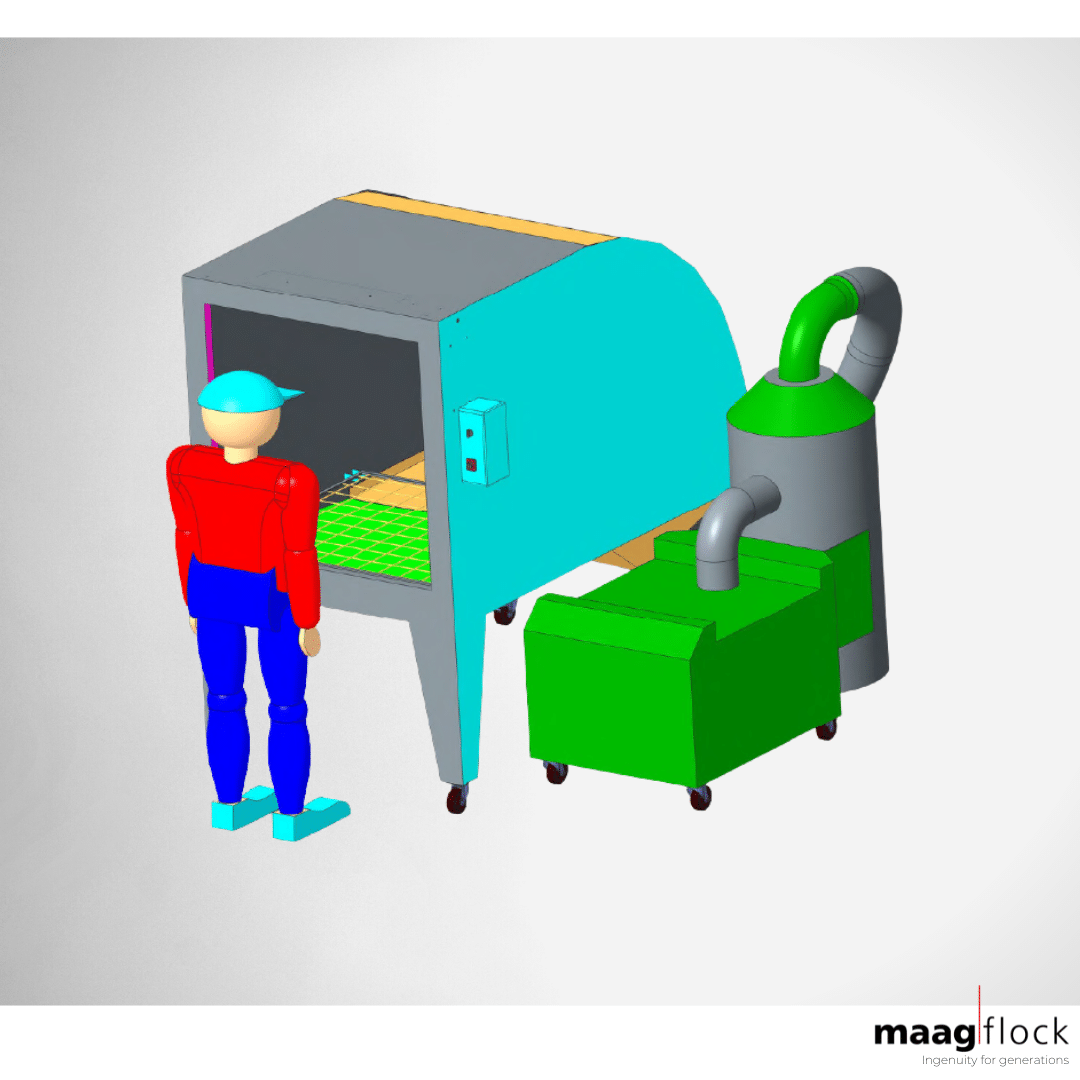

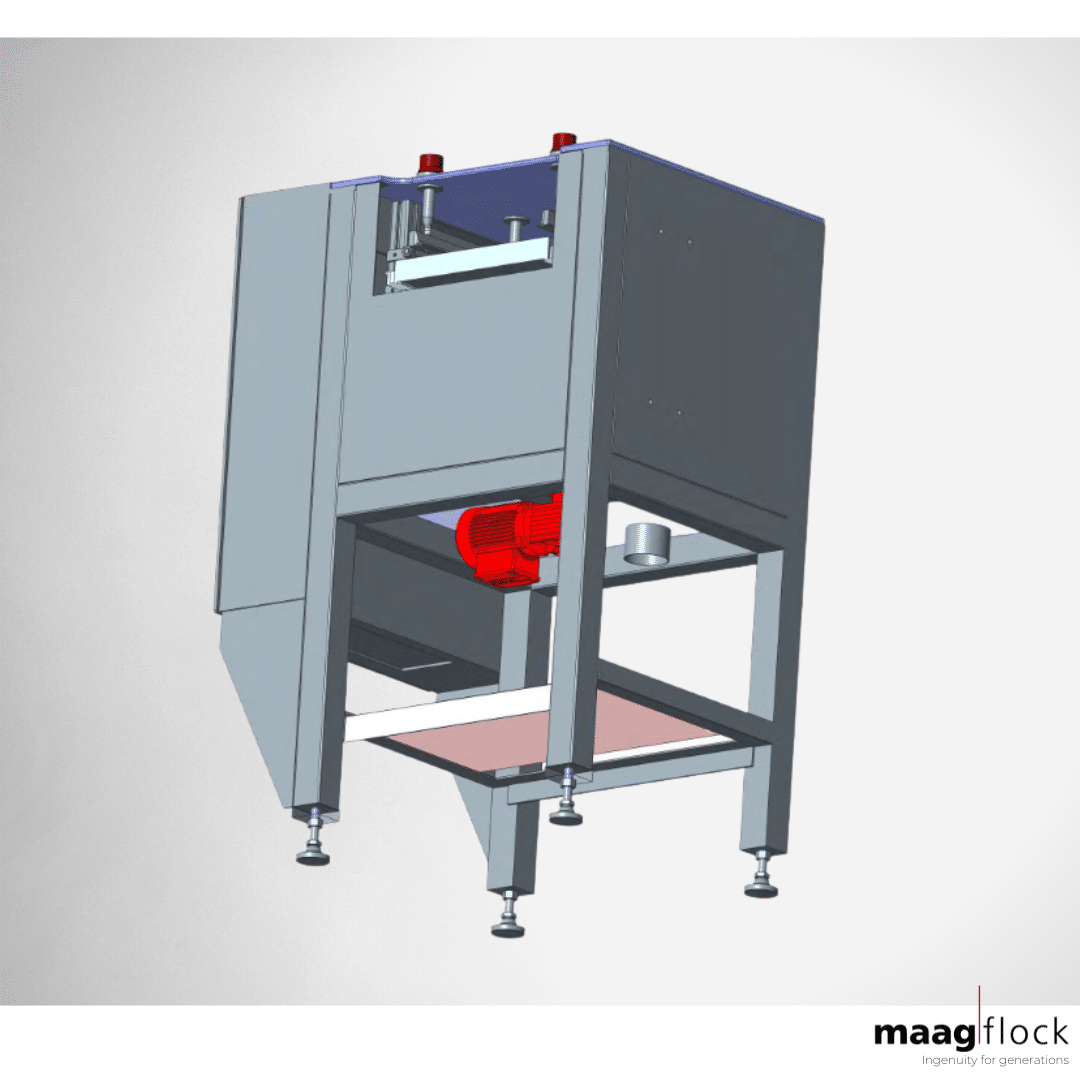

Paint roller flocking dryer

The flock dryer for paint rollers is a continuous dryer with a conveyor chain, including deflectors.

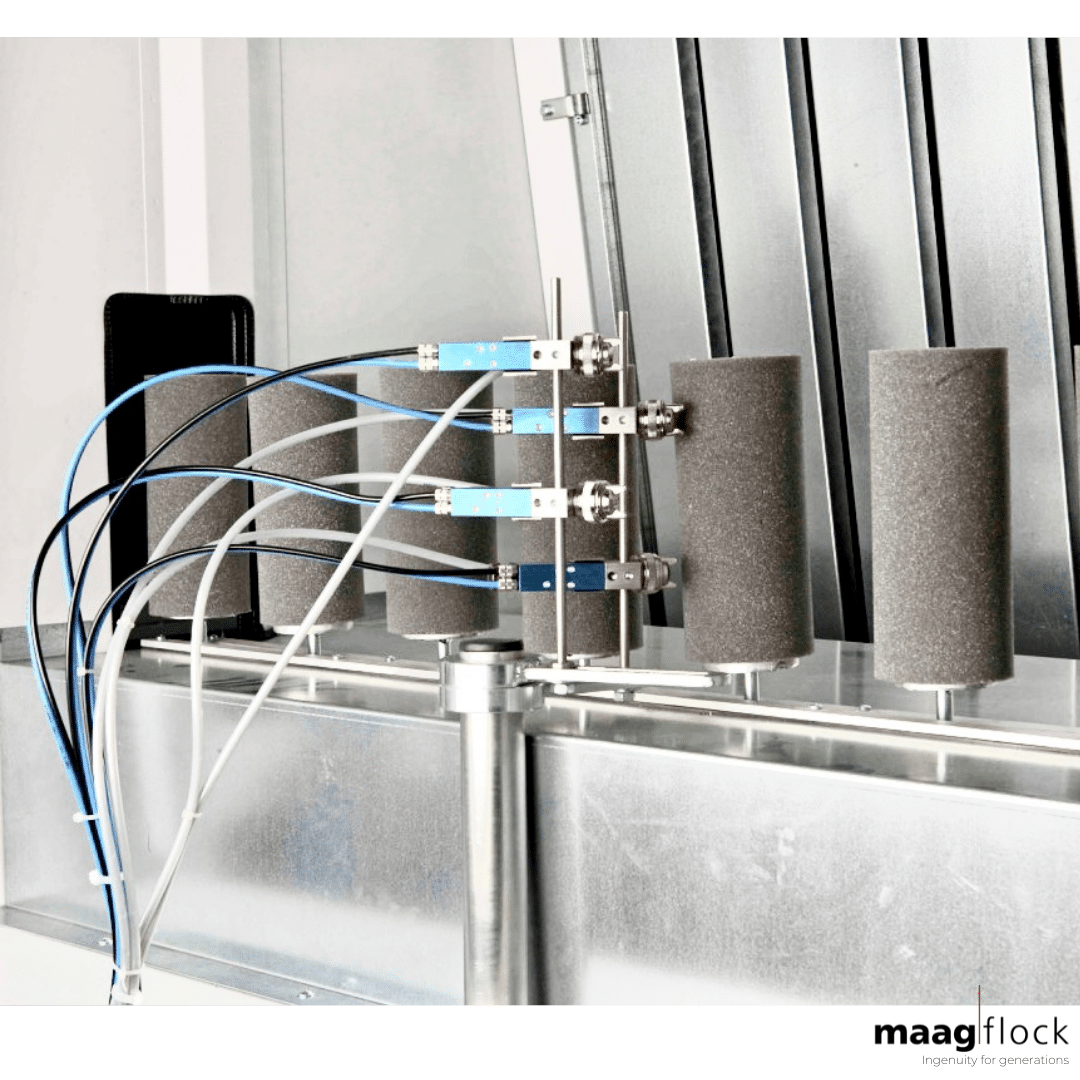

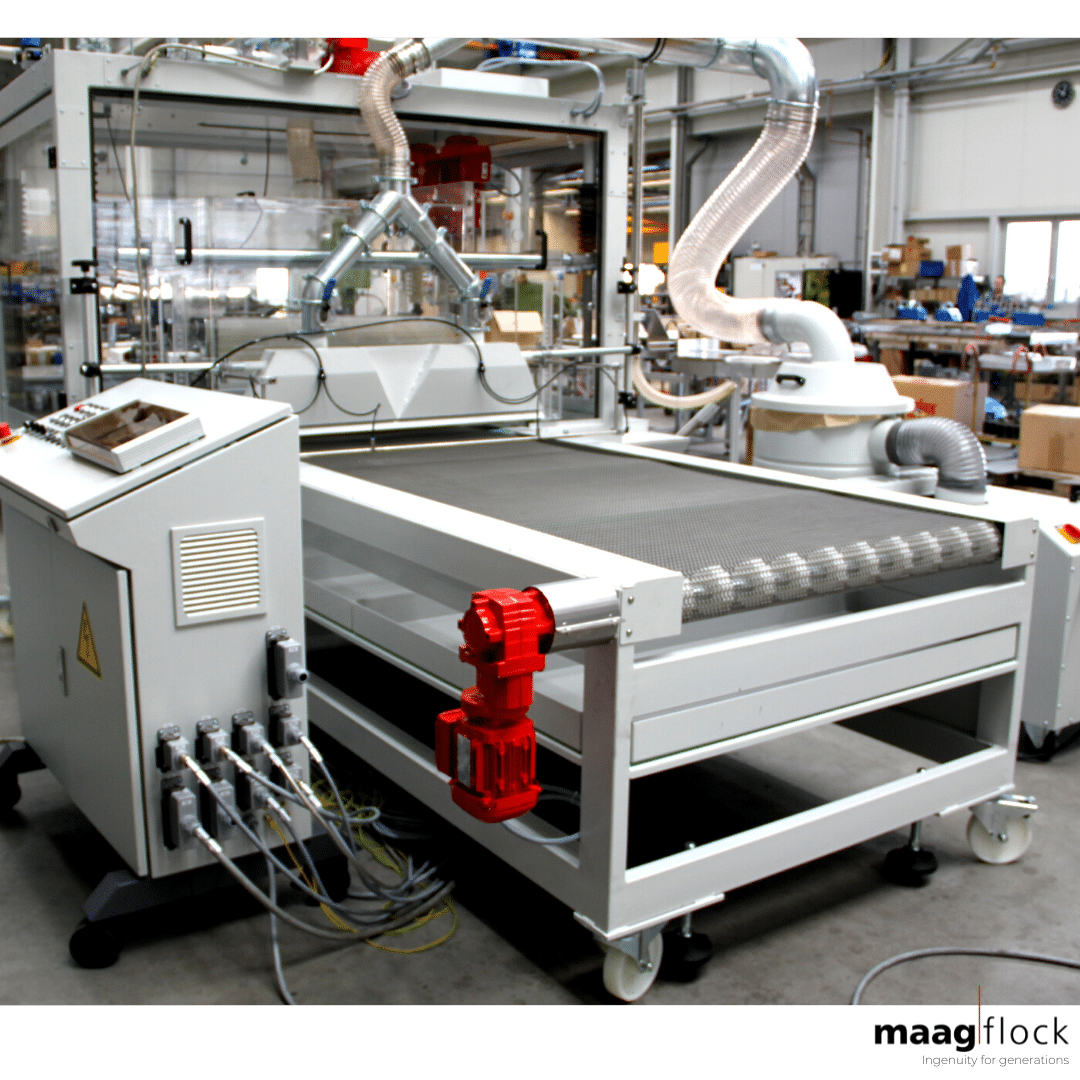

Painter roller flocking machine

Painter roller flocking machine The compact system for flocking painter rollers is characterized by the fact that the flock extraction, flock return, flock collection and flock dosing are an integral part of the actual flocking booth. The system is designed in C-construction in such a way that it can be extended and retracted into the conveying system of the entire plant. For a quick colour change, 2 flocking cabins, filled with different flocks, can also be [...]

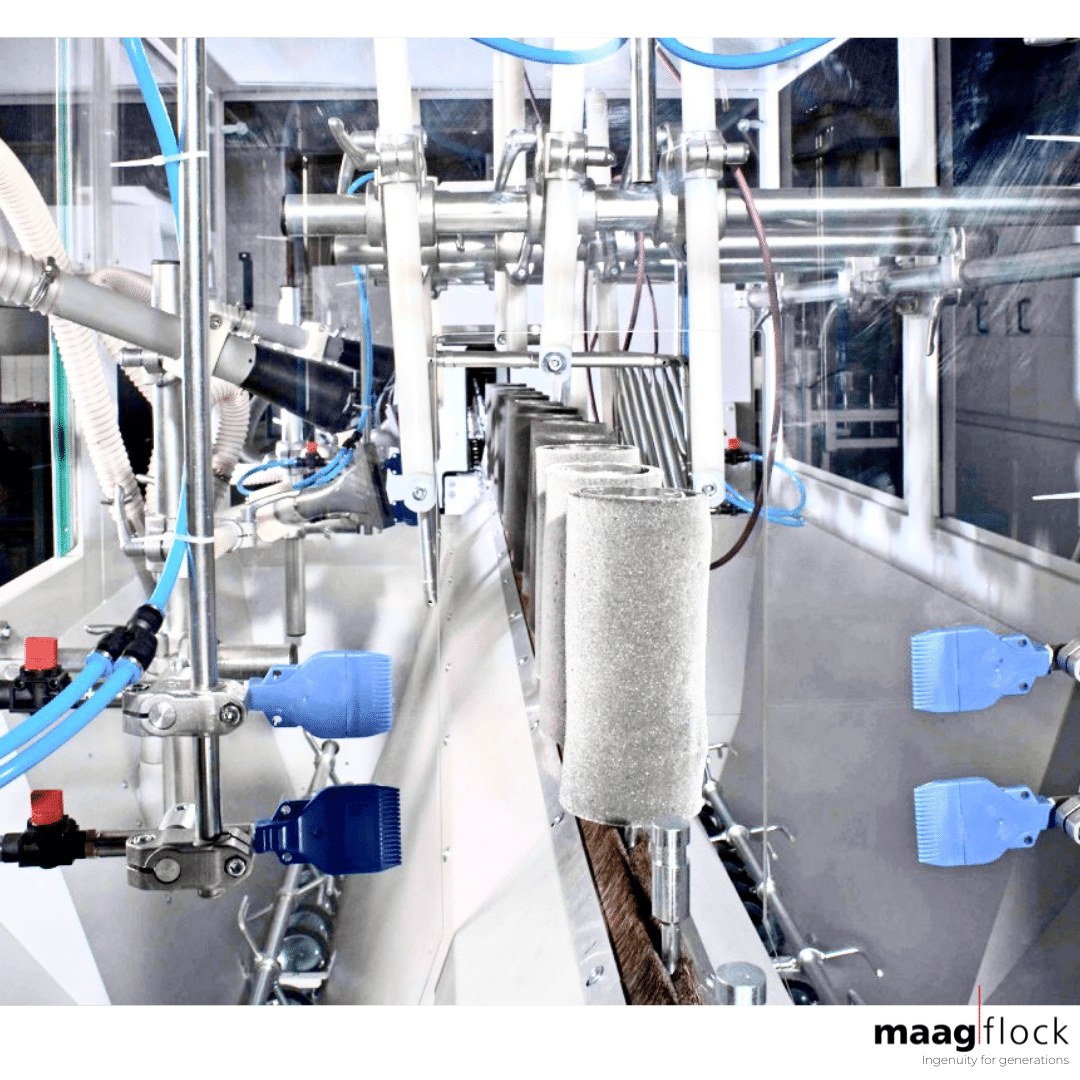

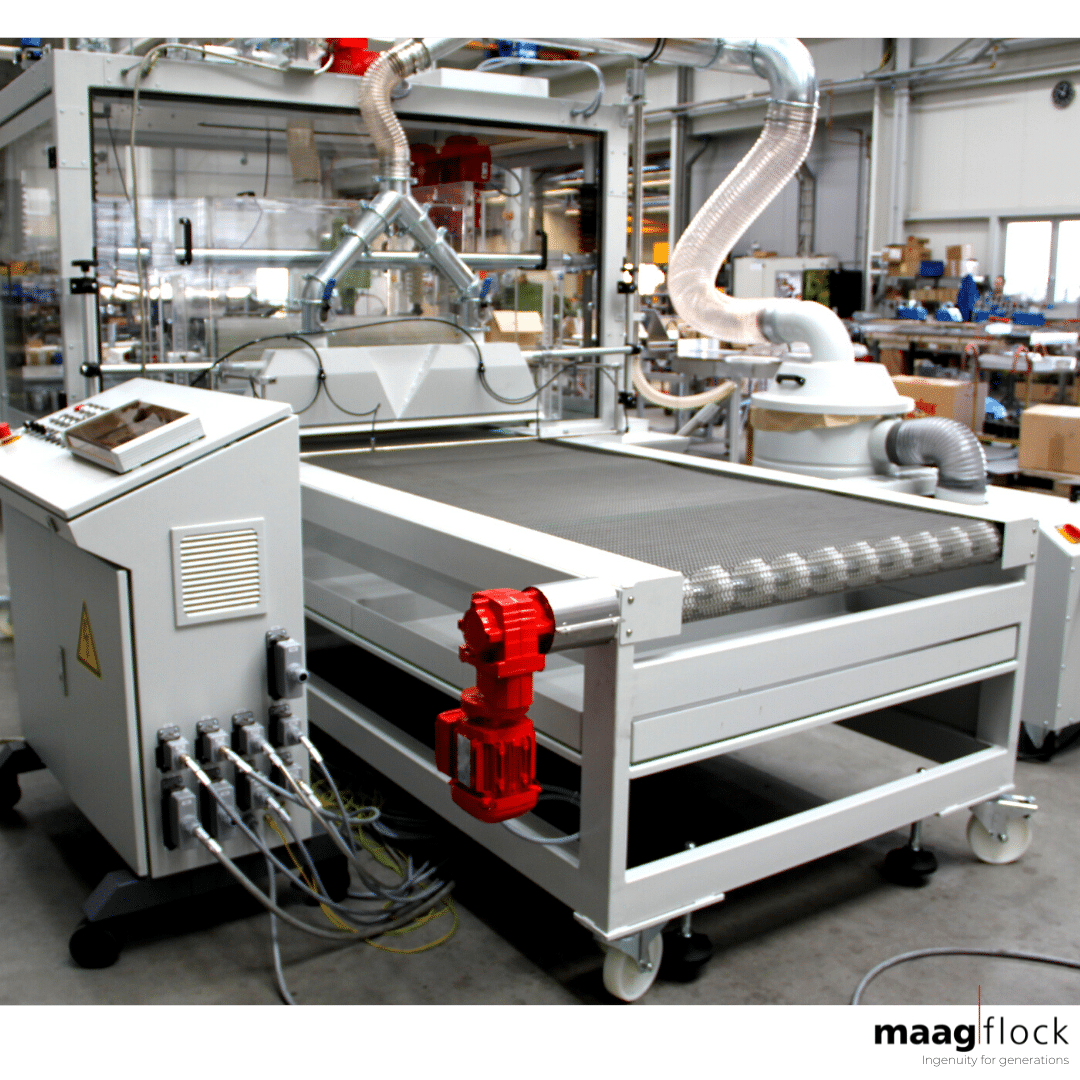

Adhesive application unit Painter roller flocking

The adhesive application unit for paint roller flocking consists of a spray booth, on the rear wall of which there is an extraction fan with a protruding filter cassette. Inside the booth the chain control for the workpiece transport is installed. The workpieces fixed on the holding devices are rotated when passing the spray nozzles. The rotation is carried out by a height-adjustable reversing belt, which drives the rotating holding devices. The workpieces run continuously past three spray guns, which are universally adjustable in three directions, and are coated with adhesive.

SWAP cleaning unit

The SWAP cleaning unit is used to clean the flocked workpieces.

SWAP flocking dryer

The SWAP flocking dryer is used to dry the flocked workpieces after flocking.

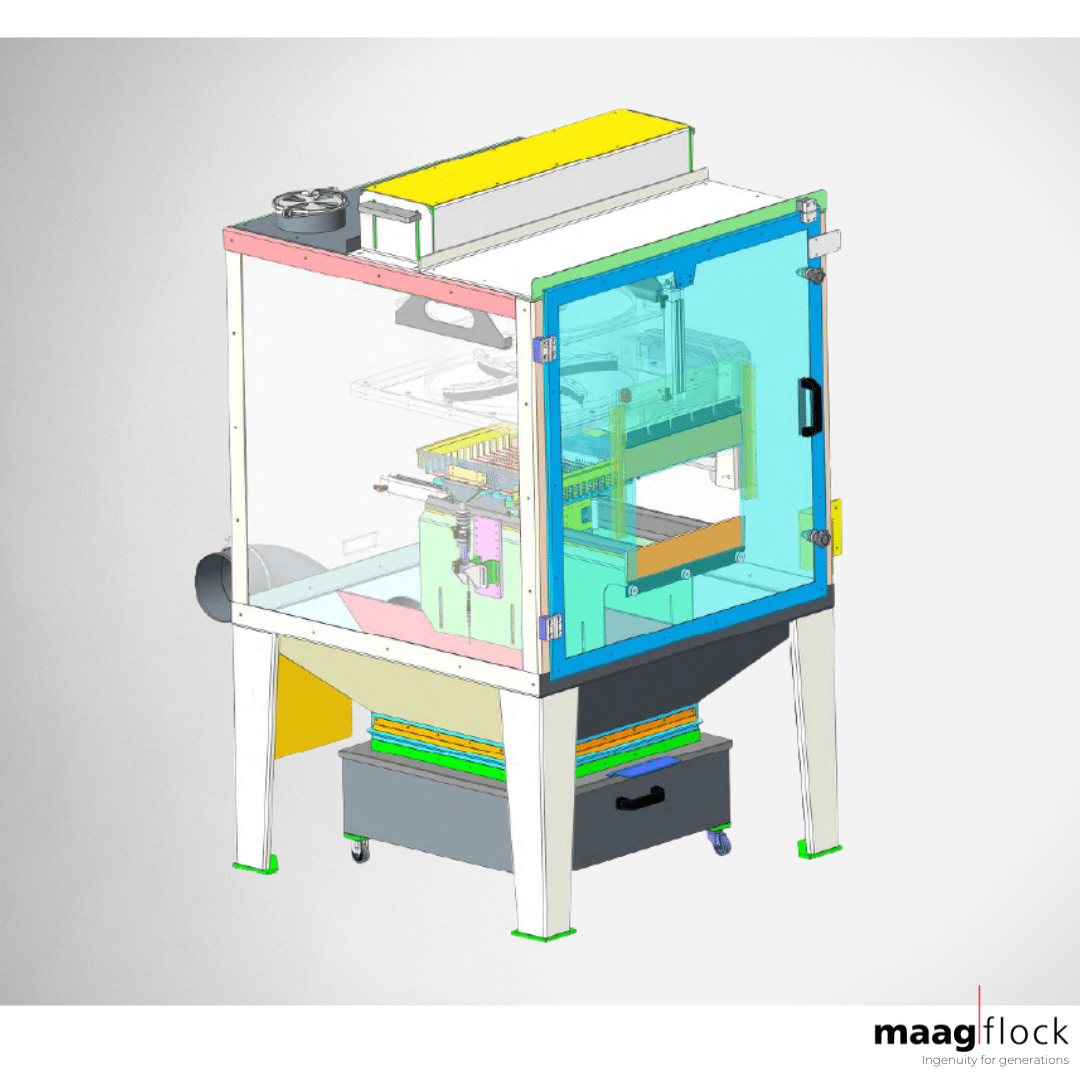

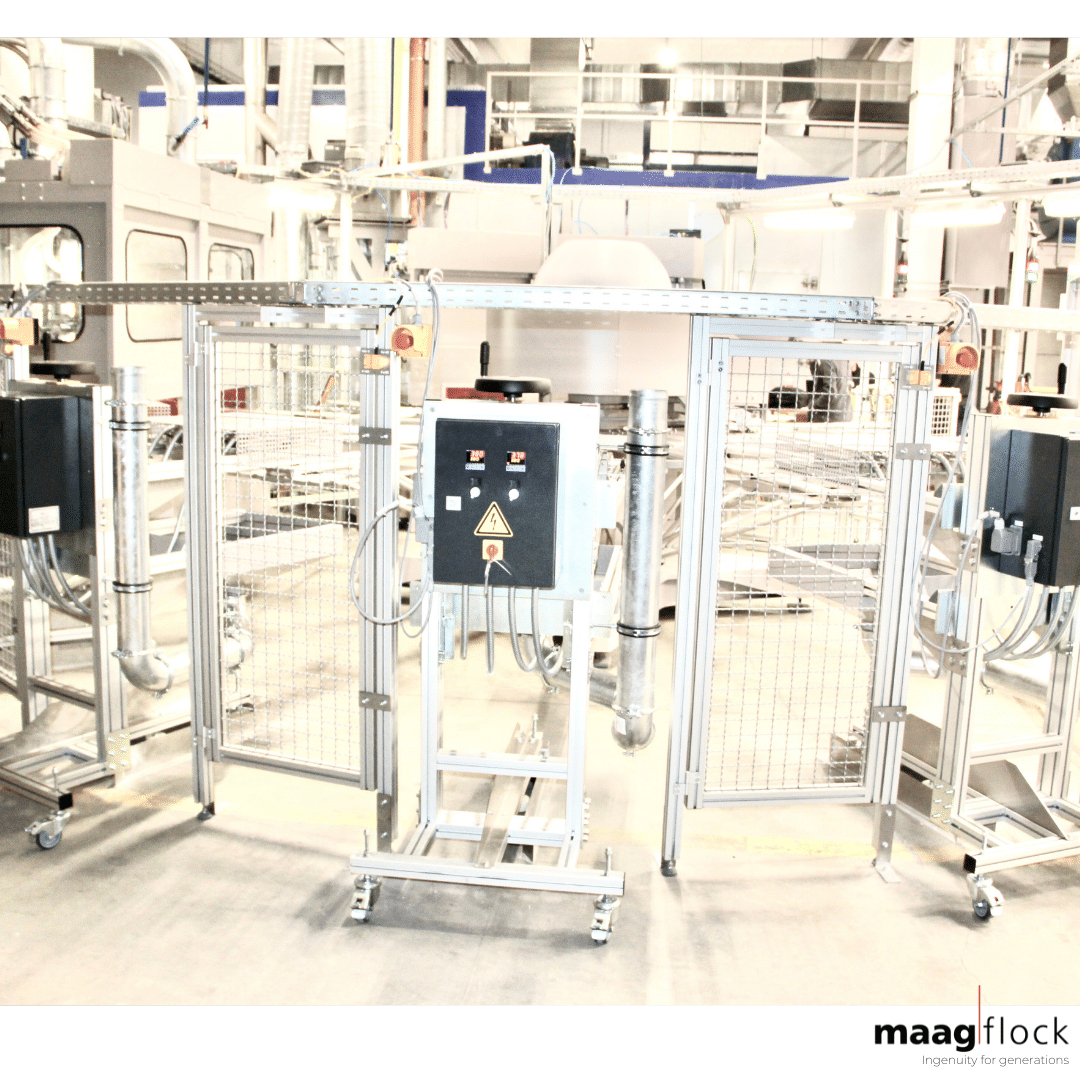

SWAP flocking machine

The SWAP flocking machine is used for flocking tips and SWAPs, e.g. for the cosmetics industry or dental medicine.

SWAP adhesive application unit

The SWAP adhesive application unit consists of a stable machine frame with integrated workpiece plate pick-up and an automatic adhesive tray feed.

Roll to roll cleaning unit

The roll to roll cleaning unit is used to clean the material to be flocked.

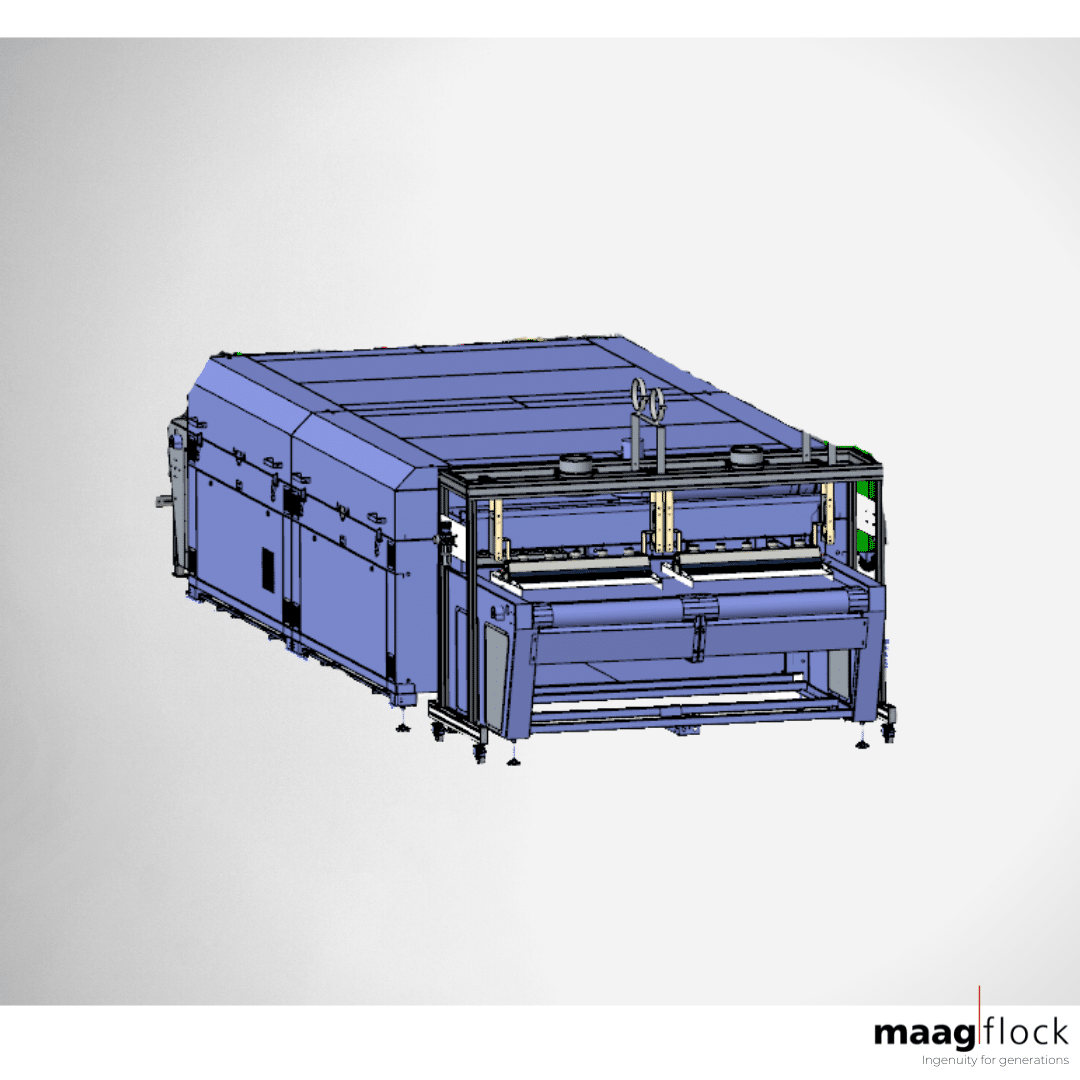

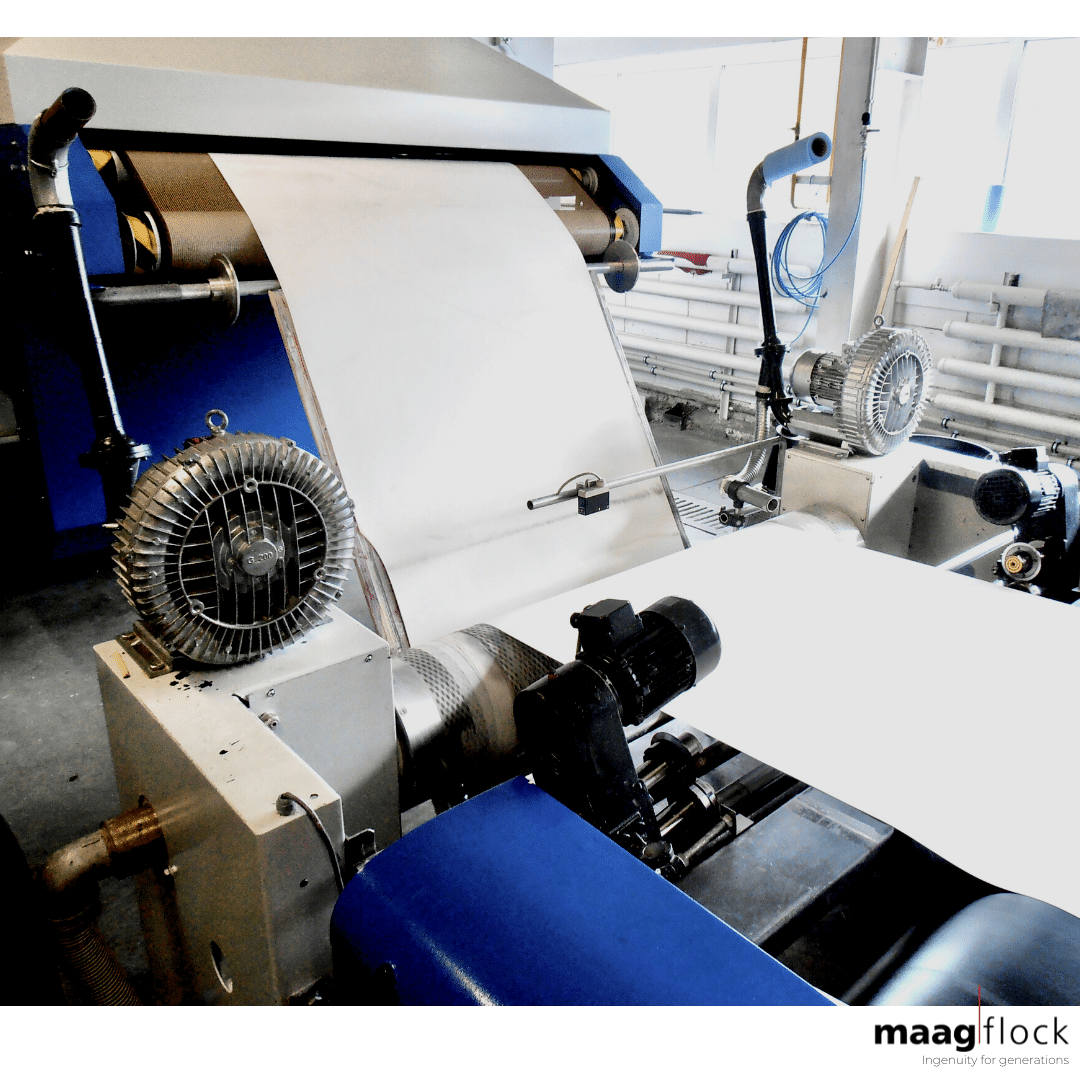

Roll to roll flocking machine

Roll to roll flocking is used for professional finishing and protection of surfaces by the flock.

Roll to roll roughening unit

The roll to roll roughening unit is used for the pre-treatment of the material to be flocked.

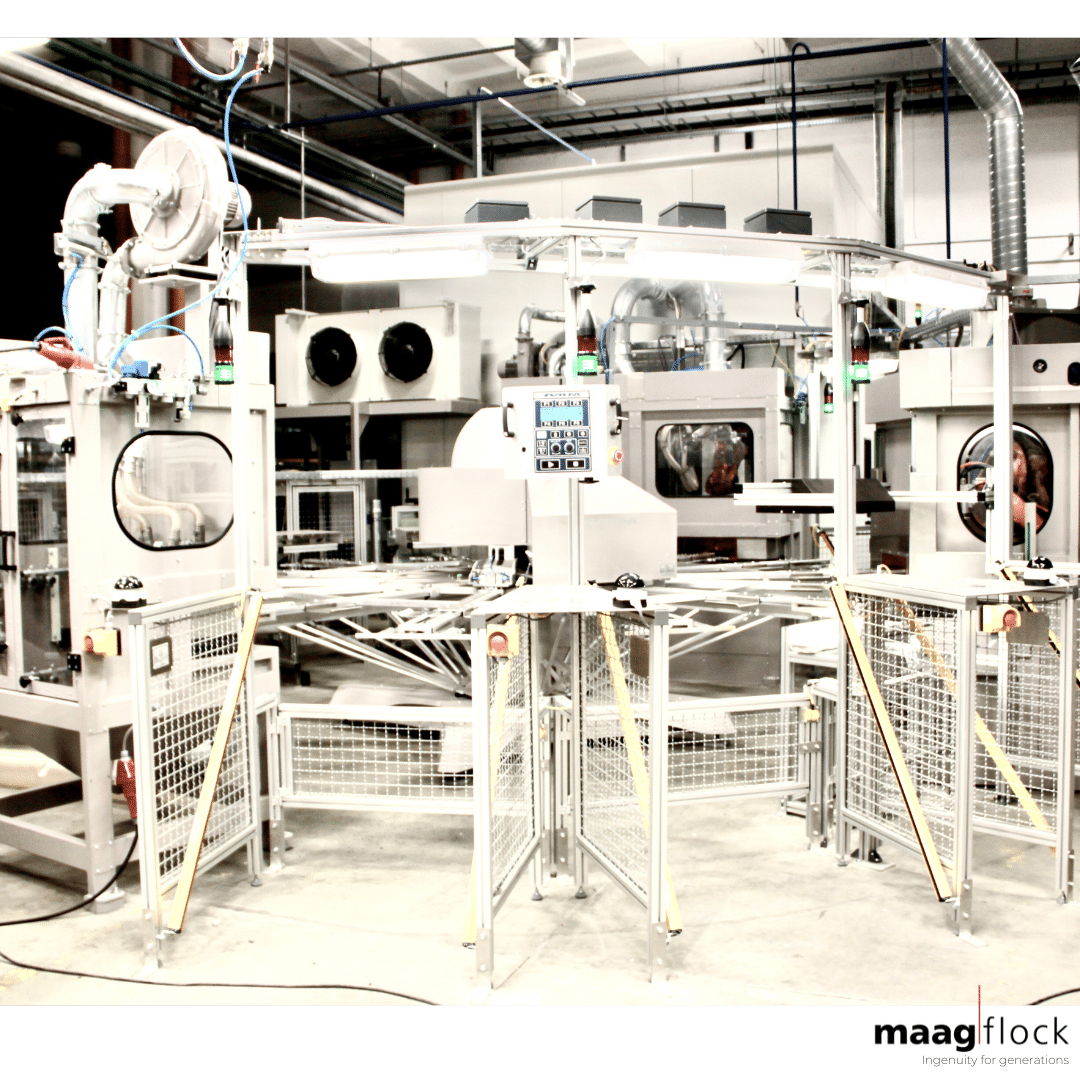

Cleaning unit corner post-flocking

The cleaning unit for corner post-flocking is used to clean the flocked parts and to extract residual flock.

Corner post-flocking dryer

Drying by means of the corner post-flocking dryer takes place through several drying stations in different working steps, whereby the total drying time is based on the splitting of individual steps.