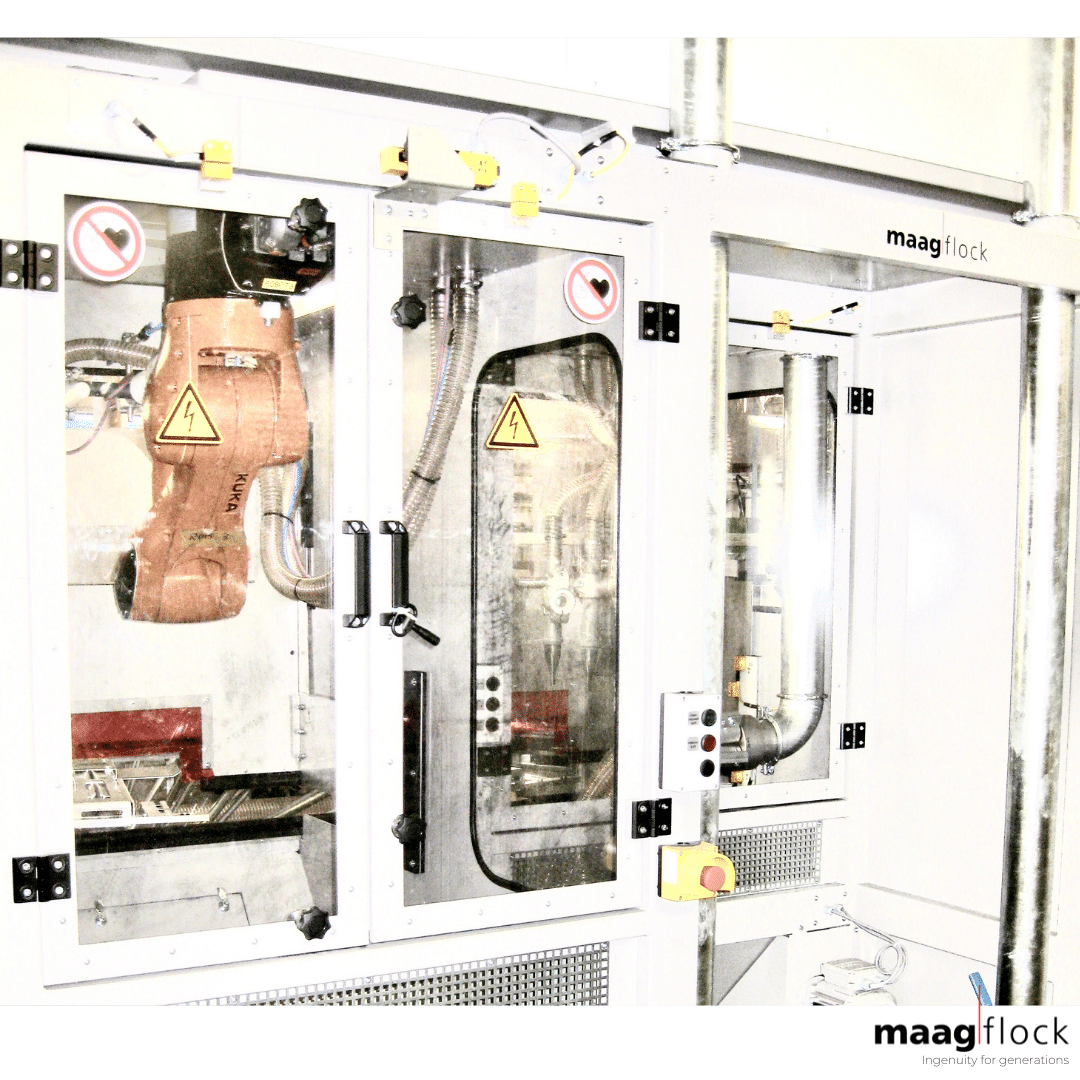

Corner flocking machine

The corner flocking machine works with an electrostatic/pneumatic flock dosing unit which is moved by a robot over the surfaces to be flocked.

Adhesive application unit for corner flocking

The adhesive application in the adhesive application unit for corner post-flocking is carried out by a 5-axis robot.

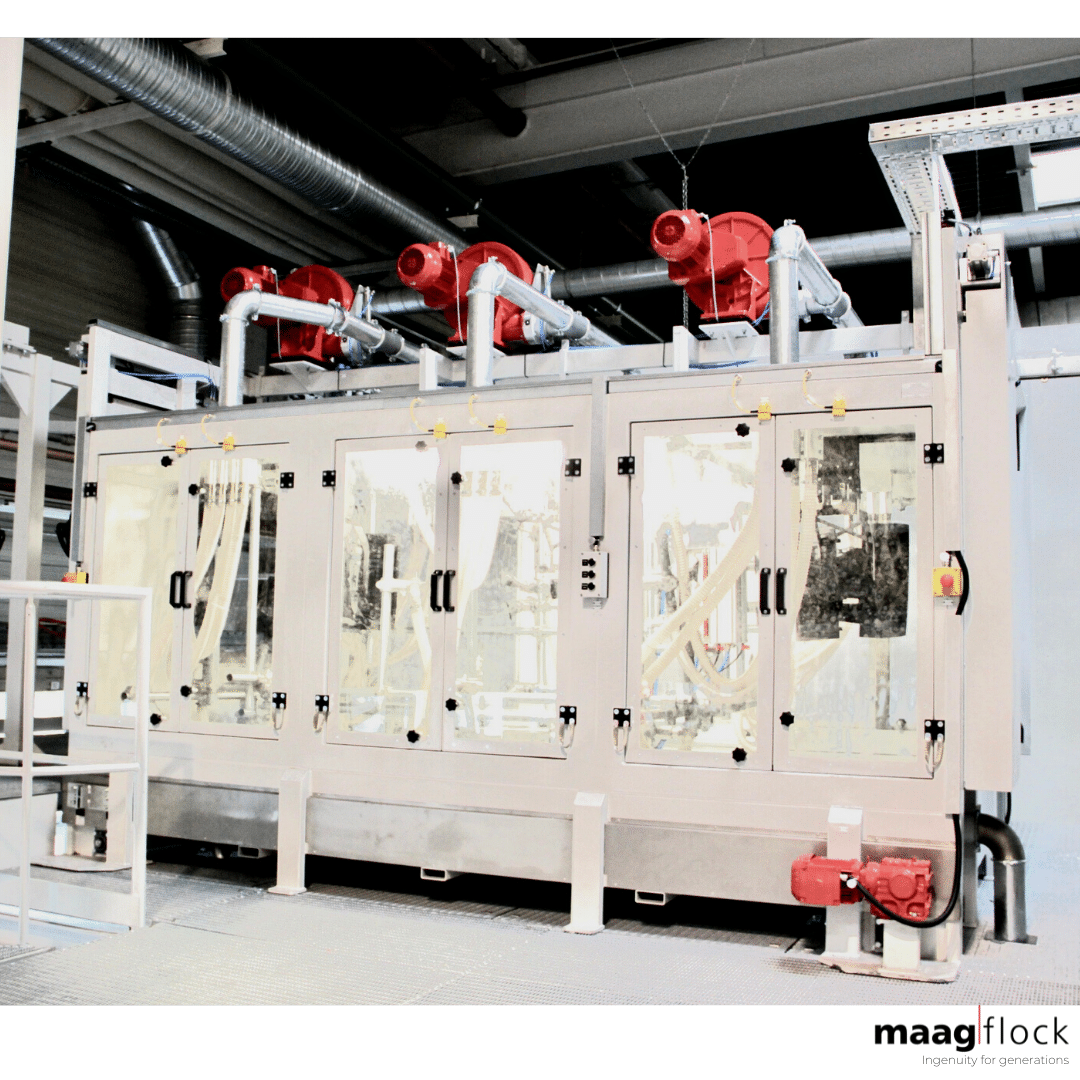

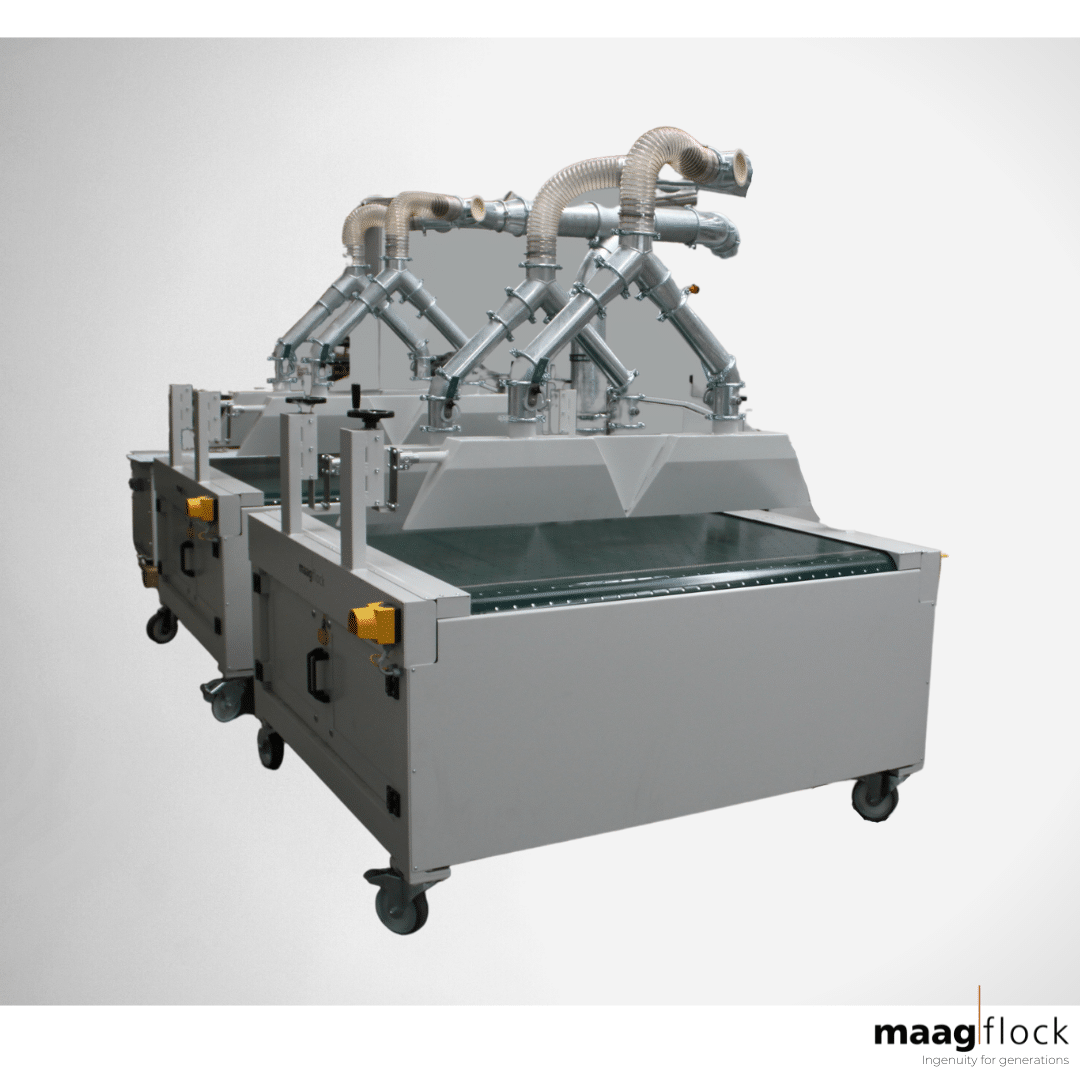

Moulded part cleaning unit

The moulding cleaning unit is externally identical in construction to the flocking or pre-cleaning unit. It extends over a total of 5 machine cycles, separated into coarse and fine cleaning.

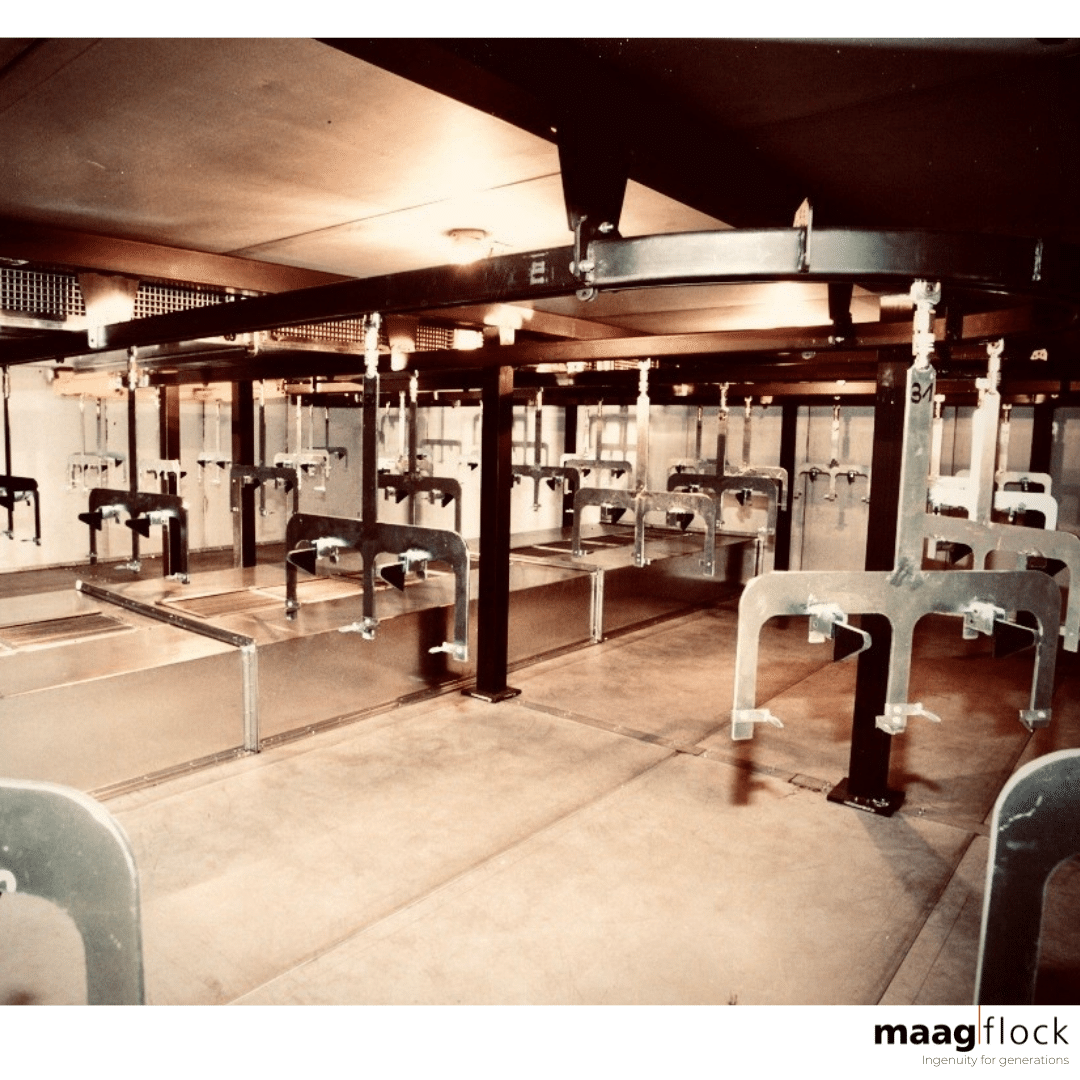

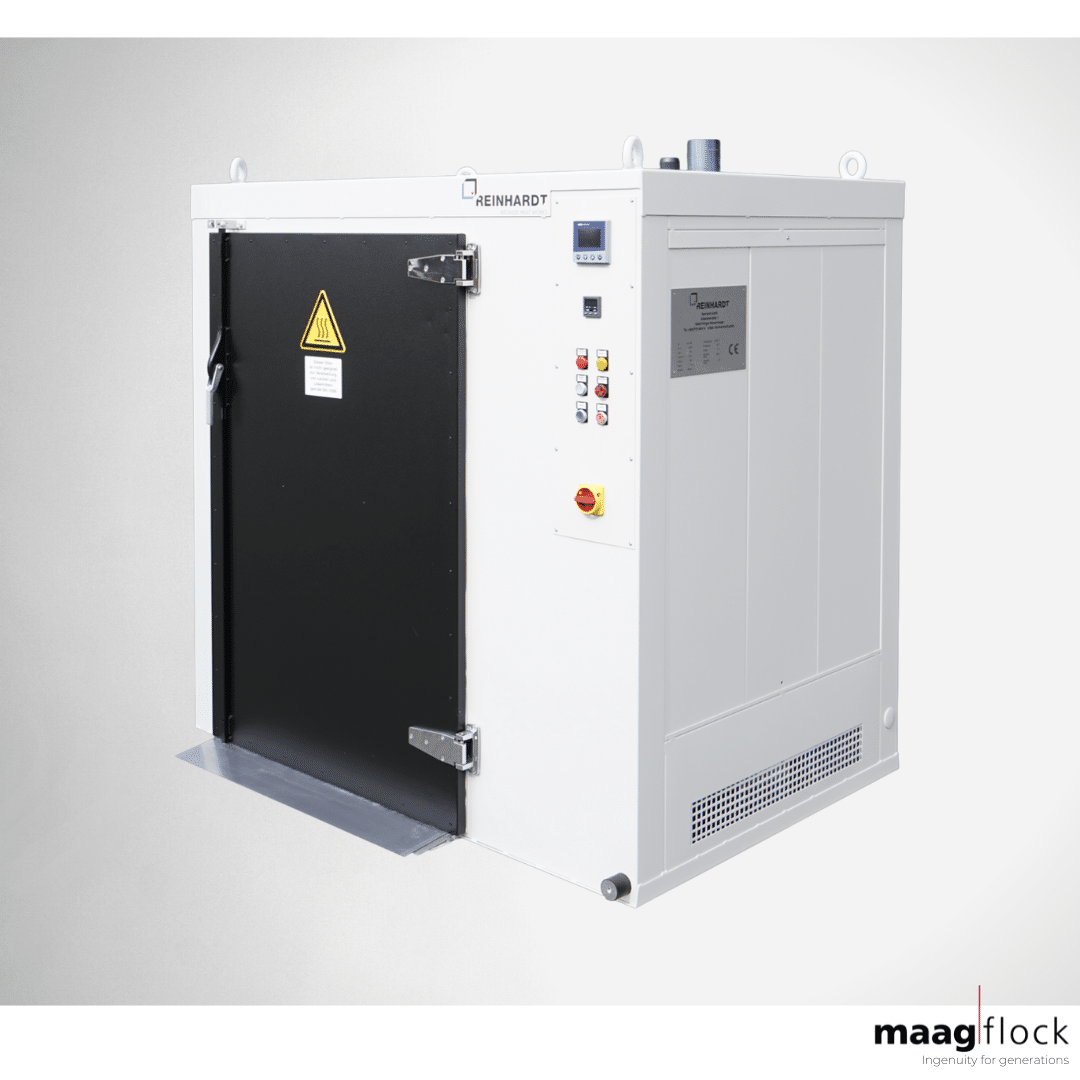

Moulding flock dryer

The moulded part flock dryer is used for drying flocked moulded parts. It consists of plate elements which are manufactured as double-walled sheet steel cassettes.

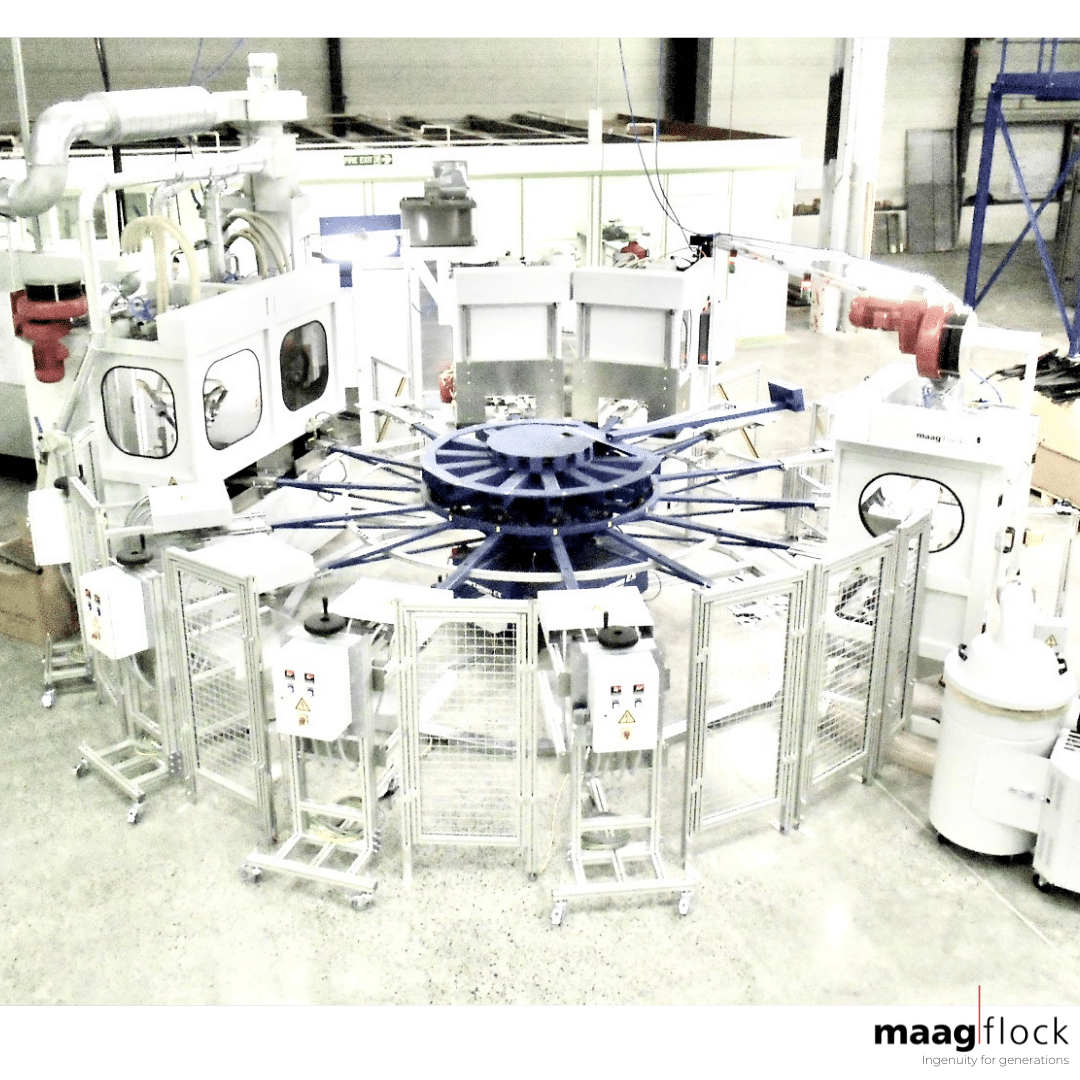

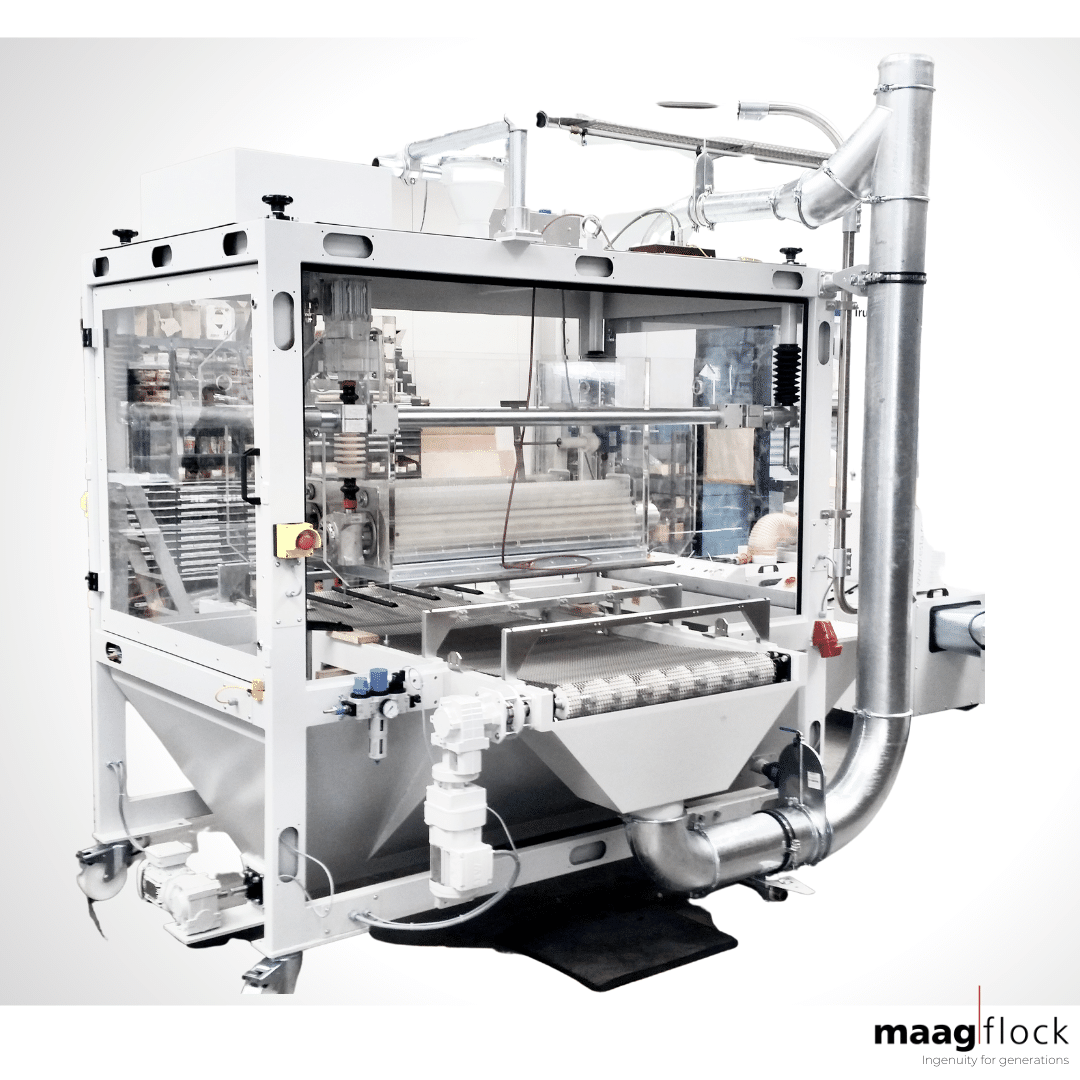

Moulding flocking machine

The moulding flocking machine is used for the automatic, electrostatic-pneumatic flocking of 2 identical or 2 different workpieces in one machine cycle.

Moulding adhesive application unit

The adhesive coating is applied in an air-conditioned robot cabin. The molded part adhesive application unit consists, among other things, of a booth with a permanently extracted spray wall of the working width 2,000 mm and the secured handling area of the robot.

Moulding pre-cleaning unit

The pre-cleaning unit is used for the pre-treatment and cleaning of workpieces to be flocked, e.g. glove boxes.

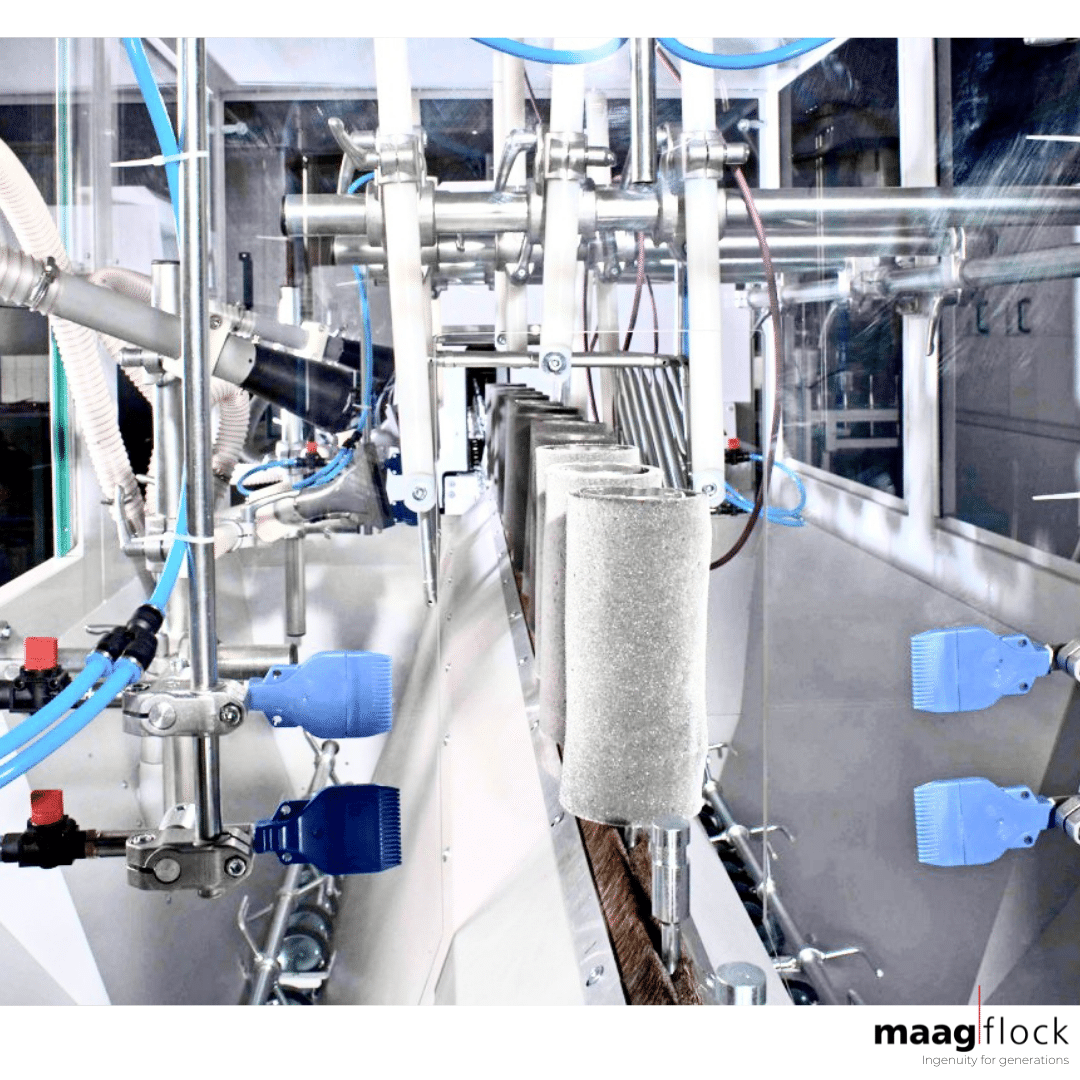

Adhesive application unit for rotationally symmetrical parts

The adhesive application unit consists of a spray booth, on the rear wall of which there is an extraction fan with a protruding filter cassette. Inside the booth the chain control for the workpiece transport is installed. The workpieces fixed on the holding devices are rotated when passing the spray nozzles. The rotation is carried out by a height-adjustable reversing belt, which drives the rotating holding devices. The workpieces run continuously past three spray guns, which are universally adjustable in three directions, and are coated with adhesive.

Flock dryer for rotationally symmetrical parts

The flock dryer for rotationally symmetrical parts is a continuous dryer with a conveyor chain, including deflectors.

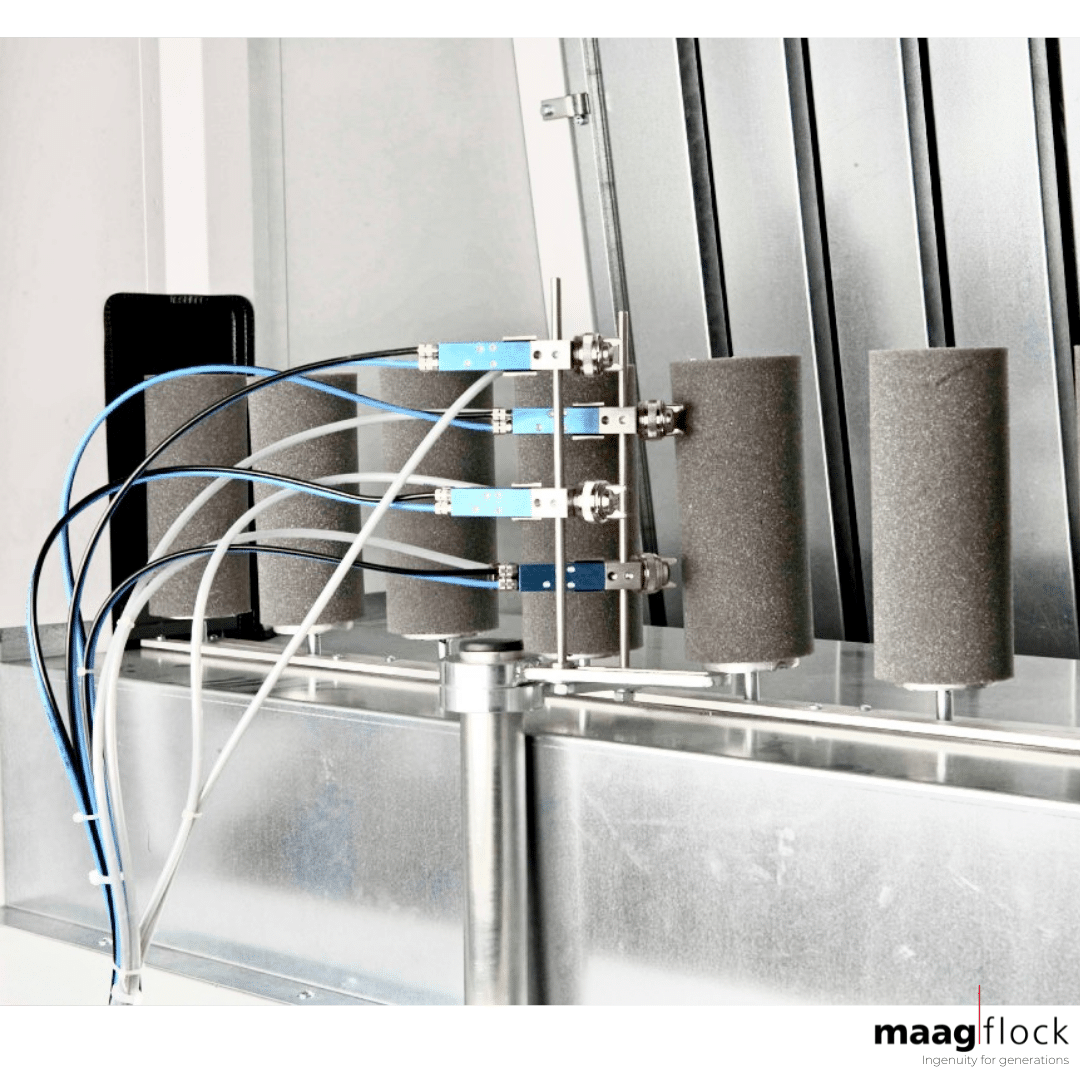

Flocking machine for rotationally symmetrical parts

The flocking machine for rotationally symmetrical parts is a compact system which is particularly suitable for small and medium-sized workpieces such as paint rollers, glasses, bottles, tool handles, etc.. Characteristic for this concept is that the flock extraction, flock return, flock collection and flock dosing are an integral part of the actual flocking booth.

Surface pretreatment and cleaning unit

The surface pre-treatment and cleaning unit ensures optimum extraction of the excess residual flock.

Surface dryer

The surface dryer is used for drying after flocking.

Surface flocking machine

The surface flocking machine is used for flocking for professional finishing and protection of surfaces. ABS and polystyrene panels, wood and hardboard panels, metal panels as well as PVC blanks and other materials can be flocked.

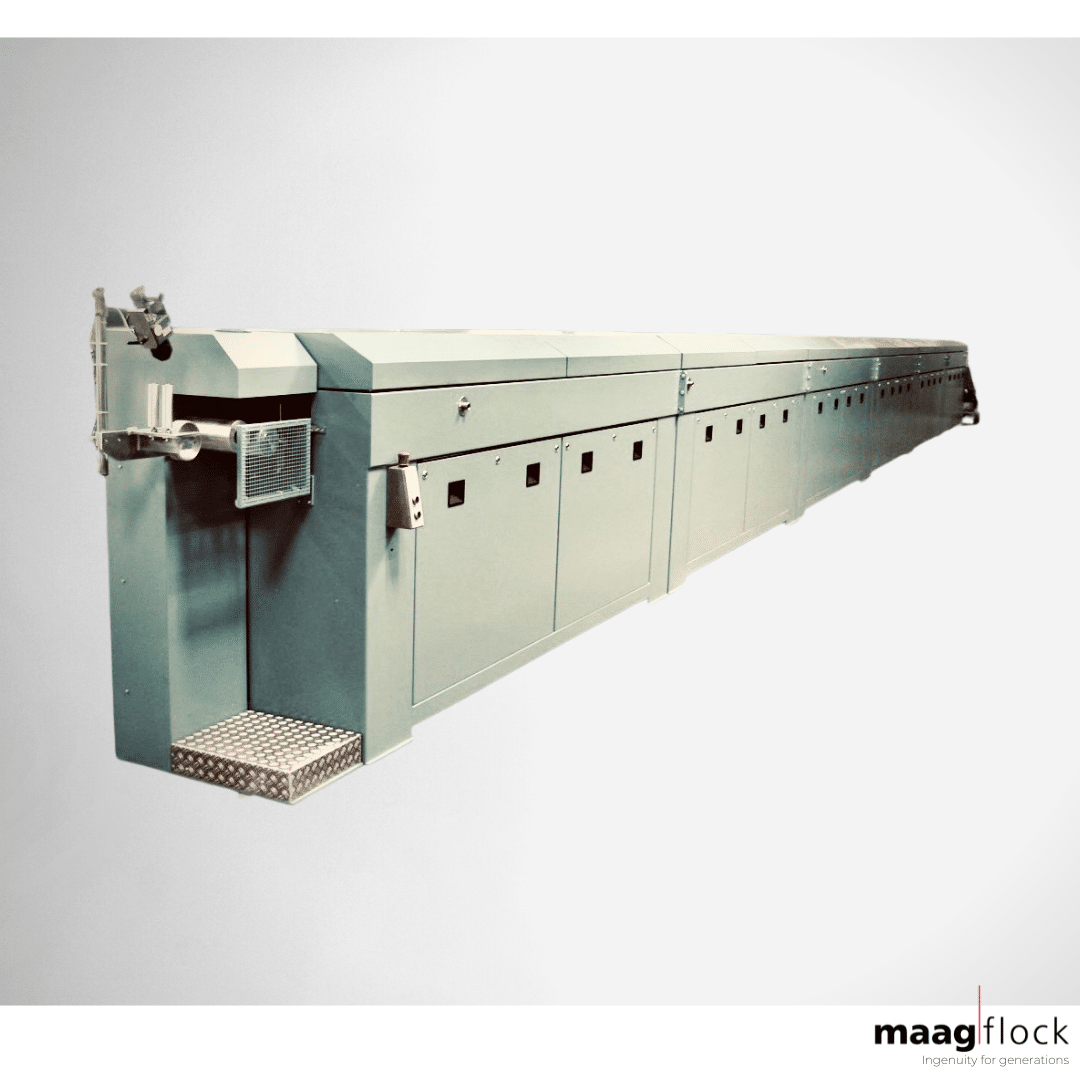

Profile dryer Maag PT

The Maag PT profile dryer is used for drying the profile. The entire drying channel is manufactured as a stable profile steel frame and can be heated electrically or with gas (hot air), among other things.

Career

Career - Working at Maag Flock We are looking for employees with personality who, true to our motto "Ingenuity for generations", inspire our customers with passion & inventiveness. Who we are Maag Flock is the world market leader as a machine builder in the flocking industry. For us, longevity and technological progress take center stage. Our corporate philosophy "Ingenuity for generations", embodies this. We can [...]